3D Printing Service in China | High Quality & Nice Price

3D printing for plastic & metal

Additive Manufacturing - Industrial 3D PrintingZ

We have been applying 3D printing to make prototypes & small lot productions for years! 3D printing, also known as additive manufacturing, is a process of creating a three-dimensional object by laying down successive layers of materials until the object is complete. We provide a wide range of 3D printing services that are frequently-used around the world: FDM, SLA, SLS and SLM. Giving us the abilities in working on versatile applications in both plastic & metal, from one-off part to small series of low volume manufacturing, and no matter how complex or intricate it is.

What is 3D Printing Exactly?

3D printing or additive manufacturing is the process of construction from digital files in computer to real. It is creating object by laying down successive layers of different materials. With its increasing affordability and the availability of new materials, 3D printing is now being used for a wide range of application, from prototyping and product development to manufacturing, and even medical applications.

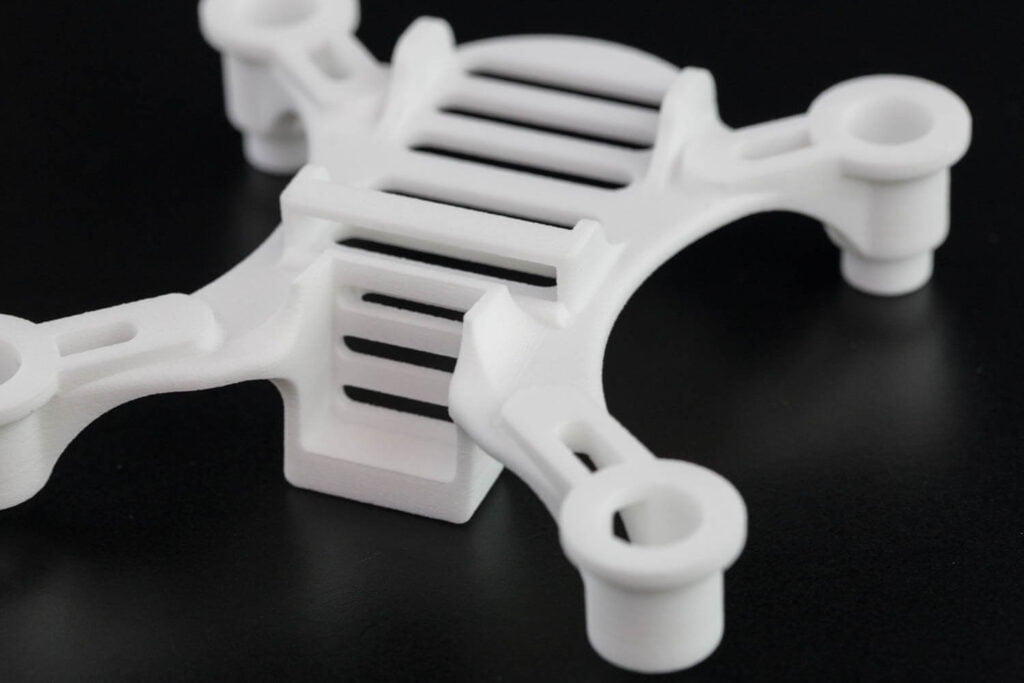

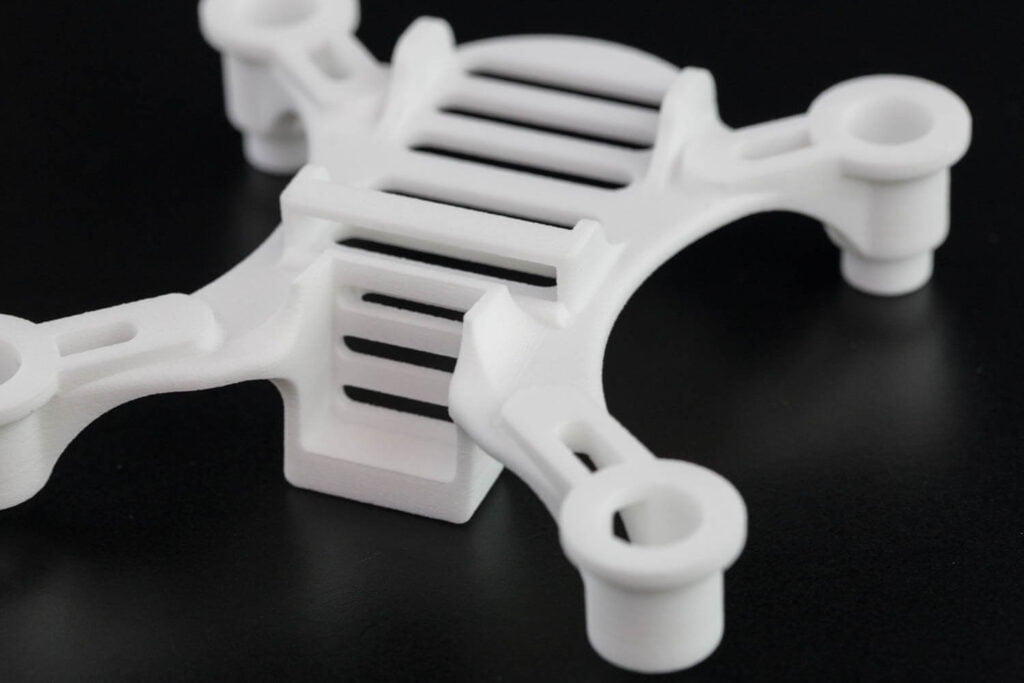

3D printing offers the ability to produce highly complex and intricate objects with a high degree of precision.

There are several different 3D printing technologies available, including Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Direct Metal Laser Sintering (SLM). Each technology has its own advantages and disadvantages, and the choice of which to use will depend on the specific requirements of the project.

FDM, SLA, SLS & SLM, which is the best to you?

Fused Deposition Modeling (FDM) is the most commonly used 3D printing technology. It works by heating and extruding plastic filament, which is then deposited layer by layer until the object is complete. FDM is popular because it is relatively low-cost and has a wide range of materials available, including different types of plastic, wood, and even metal. It is also relatively easy to use, making it a great option for hobbyists and beginners.

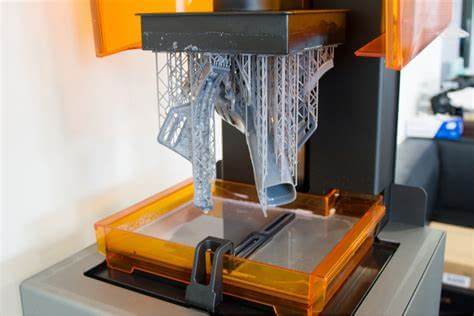

Stereolithography (SLA) is a more advanced 3D printing technology that uses a laser to cure a photo-sensitive resin into a solid object. SLA is more accurate than FDM, with a higher resolution and smoother surface finish. It is also capable of producing objects with finer details, making it a popular choice for producing intricate models and prototypes. However, SLA is more expensive and has a limited range of materials available compared to FDM.

Selective Laser Sintering (SLS) is another advanced 3D printing technology that uses a laser to fuse together particles of nylon powder into a solid object. SLS is capable of producing complex objects with high levels of accuracy and detail, and is often used for producing functional prototypes and end-use products. However, SLS is more expensive than FDM and SLA, and requires a specialized powder bed for printing.

Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM) is an advanced additive manufacturing technology used to create 3D objects from metal powder. It is a type of 3D printing that uses a high-powered laser to selectively melt and fuse together metal particles to create a solid, three-dimensional object. The main advantage of DMLS is its ability to produce complex, high quality metal parts with a high degree of accuracy and details.

The Advantages of 3D Printing

- Design flexibility: 3D printing allows for the creation of complex geometries and intricate designs that would be difficult or impossible to produce with traditional manufacturing methods.

- Reduced costs: 3D printing eliminates the need for expensive tooling and production runs, reducing costs and increasing cost-effectiveness for low-volume production.

- Faster production times: 3D printing enables faster design iterations and rapid prototyping, reducing the time it takes to go from concept to final product.

- Innovation and experimentation: 3D printing allows for experimentation and innovation in design and materials, leading to new products and applications.

- Access to hard-to-find parts: 3D printing can be used to produce replacement parts that may be difficult to source or no longer available.

What can we do with 3D Printing?

3D printing allows for fast and cost-effective production of parts and prototypes. Here are some of the ways 3D printing can be used for rapid prototyping or small volume production:

Product design and development: 3D printing allows designers and engineers to quickly produce prototypes of new products, test and refine them, and make improvements before committing to full-scale production by injection molding.

Functional testing: 3D printed parts can be used for functional testing to ensure that they work as intended before committing to expensive tooling and production runs, similar with vacuum casting.

Customization: 3D printing allows for easy customization and personalization of products, making it possible to meet specific customer needs and preferences.

Tooling and fixtures: 3D printing can be used to produce tooling and fixtures for manufacturing processes, reducing costs and lead times.

Small-batch production: 3D printing is well-suited for small-batch production of parts and products, allowing for faster turnaround times and lower costs compared to traditional manufacturing methods like CNC machining.

Replacement parts: 3D printing can be used to produce replacement parts for machinery and equipment that may be difficult or expensive to source through traditional channels.