Vacuum Casting and Color Customization: How to Get the Best Results

Vacuum casting is a popular method for producing plastic parts in small volumes. However, when it comes to color customization, vacuum casting presents some challenges. Adding pigments to the casting material can result in surface imperfections by parting lines and destroy the exterior cosmetic surface, and it is difficult to fix manually after the plastic parts are vacuum casted. Moreover, we have to manually remove burrs or improve the exterior cosmetic surface for the vacuum casted parts, which will also destroy the outlook and brings surface imperfections. In this blog post, we will explore a solution to this problem: spray painting the exterior surface of vacuum casted parts to achieve the desired color, while keeping the interior in its natural color.

- Step 1: Vacuum Casting in Natural Color

The first step in this process is to vacuum cast the part in its natural color, which is typically white or translucent. This is done to ensure that the interior of the part remains clean and free from any pigments that could affect its mechanical properties or performance. Vacuum casting in natural color also allows for easier quality control and inspection, as any defects or impurities will be more visible.

- Step 2: Surface Preparation

Once the part is vacuum casted, it’s time to prepare the exterior surface for painting. This involves cleaning the surface to remove any dust, oil, or other contaminants that could affect the adhesion of the paint. Sanding or polishing may also be necessary to smooth out any part lines or surface imperfections. It’s important to be careful during this step, as any damage to the exterior surface could compromise the overall quality of the part.

- Step 3: Spray Painting

With the surface properly prepared, it’s time to apply the paint. Spray painting is the preferred method for this application, as it provides an even coat of paint and allows for precise control over the color and finish. It’s important to choose a paint that is compatible with the casting material and can withstand any environmental or chemical exposure that the part may encounter in its end-use application.

- Step 4: Quality Control and Inspection

After the paint has dried, the part should be inspected for any defects or imperfections. This is an important step, as any flaws in the painted surface could detract from the overall quality and aesthetics of the part. It’s also a good idea to perform some basic tests on the part to ensure that the paint has not affected its mechanical properties or performance.

Just one catch that we want to highlight at the end:

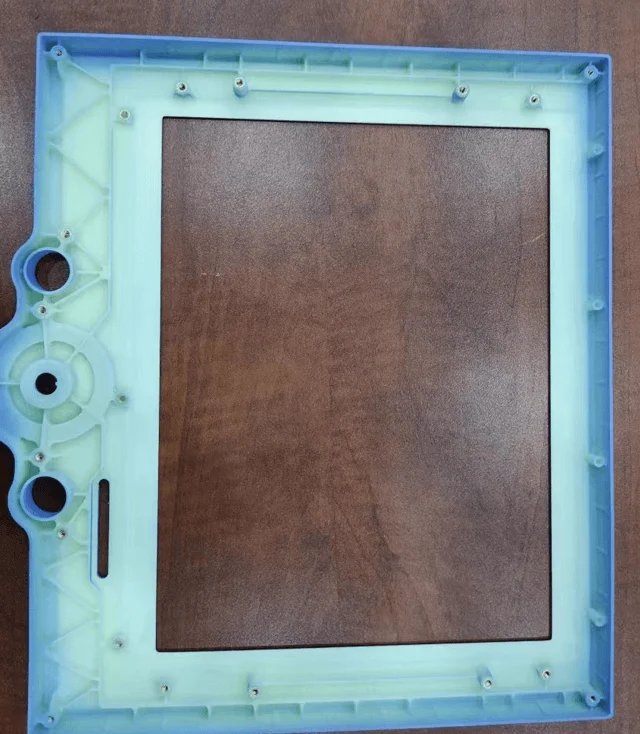

The interior surface of the vacuum casted plastic parts is not suggested for color customization by spray painting. There are always jigs & fixtures to support the vacuum casted plastic part during the spray painting, there are contact points on the interior surface; moreover, there are always ribs & caves inside the vacuum casted plastic parts itself, which make it is a bit hard to get perfect color customization inside; In our factory, our customers always just leave it the natural colors, and please refer to below images for detail of the color customization on the exterior surface, as well as what the interior surface looked.

If you have any query regarding the color customization for vacuum casting, or need any vacuum casting service, please feel free to visit: Vacuum Casting from China | The Ideal Solution to Small Series Manufacturing in 2023! (vacuumcastingsz.com).

https://karimmassimov.com/

karimmassimov.com e3a63d8

Hello, Jack speaking. I’ve bookmarked your site and make it a habit to check in daily. The information is top-notch, and I appreciate your efforts.

stories viewer stories viewer .

instagram viewer http://anstoriesview.com/ .

view instagram stories view instagram stories .

instagram story viewer and downloader instagram story viewer and downloader .

Mating Press I very delighted to find this internet site on bing, just what I was searching for as well saved to fav

apk 1win telecharger1winci.com .

Strands Hint I’m often to blogging and i really appreciate your content. The article has actually peaks my interest. I’m going to bookmark your web site and maintain checking for brand spanking new information.

Isla Moon Good post! We will be linking to this particularly great post on our site. Keep up the great writing

Back Magazin I truly appreciate your technique of writing a blog. I added it to my bookmark site list and will

kotor bay property for sale Montenegro property sales

buy flat Montenegro realestate

Office supplies Promo Codes [url=https://skidki-i-kupony.ru]https://skidki-i-kupony.ru[/url] .

Jugabet bonos Jugabet bonos .

Reliable HVAC Repair Services https://serviceorangecounty.com stay comfortable year-round with our professional HVAC repair services. Our experienced team is dedicated to diagnosing and resolving heating, cooling, and ventilation issues quickly and effectively.

betovo login betovo login .

Noodlemagazine naturally like your web site however you need to take a look at the spelling on several of your posts. A number of them are rife with spelling problems and I find it very bothersome to tell the truth on the other hand I will surely come again again.

myspace.com https://gratisafhalen.be/author/humoranimal48// .

myspace.com http://bookmarkstore.download/story.php?title=click-here-for-more-information-about-xxxc#discuss/ .

스포츠 베팅 스포츠 베팅 .

Biography of Spanish footballer Pedri https://pedri-bd.com statistics at Barcelona, ??games with teammate Gavi, inclusion in the national team for Euro, meme with Cristiano Ronaldo.

stamp maker stamp maker .

rubber stamp maker online rubber stamp maker online .

SportyBet registration SportyBet registration .

Noodlemagazine This is my first visit, and I’m thrilled to see everything so well organized in one location

I am apart of a commitee that is trying to start a clothing company. I am in charge of designing the clothing website because for right now you can only order stuff online. But I was just wondering how do you start a website for a clothing company? What are some good domain places to sign up for a domain..

business movers [url=spmovers12.com]spmovers12.com[/url] .

cannabis shop in prague prague 420

Check out Sellvia on Instagram for the hottest product ideas, store upgrades, and exclusive deals! Stay in the loop with our latest dropshipping tips and grab promo coupons to boost your business.

Reliable and unique bip39 Word List contains 2048 words needed to create seed phrases in crypto wallets. Allows you to safely manage private keys and guarantees the possibility of recovering funds.

Reliable and unique bip39 Word List contains 2048 words needed to create seed phrases in crypto wallets. Allows you to safely manage private keys and guarantees the possibility of recovering funds.

1xBet promo code http://www.emotionalgamesawards.com/1xbet-bonus/maximize-your-play-with-the-1xbet-promo-code-free-2/ your chance to get bonuses on bets, free bets and exclusive promotions! Enter the code during registration and start playing with an increased deposit.

cannabis shop in prague https://sale-weed-prague.com

furniture transportation Prague transfer services from Prague airport

The most comprehensive bip39 phrase for securely creating and restoring cryptocurrency wallets. Learn how mnemonic coding works and protect your digital assets!

Free and reliable nudify ai tool to create images with AI? The Best Free AI Nudify is the best choice for creating nude photos with privacy and quality guarantee.

Sitio web oficial jude-bellingham.com.mx/ de fans de Jude Bellingham: noticias, logros y material exclusivo sobre la carrera del talentoso mediocampista que juega en el Real Madrid.

Sitio web de fans http://rodri.com.mx de Rodri Hernandez: Descubre la carrera y logros del mediocampista espanol del Manchester City. Noticias, estadisticas y analisis del juego de uno de los mejores futbolistas actuales.

Kevin De Bruyne kevin-de-bruyne.com mx es un maestro del futbol moderno, conocido por su vision de juego, precision y liderazgo en el Manchester City. Su talento y trabajo duro lo han convertido en una leyenda del deporte.

Sitio fan de Mohamed Salah https://mohamed-salah.com.mx ultimas noticias, records, entrevistas y los mejores momentos de la carrera de uno de los futbolistas mas grandes de la actualidad. ?Mantente al tanto!

Fan site de Vinicius Junior vinicius-jr.com.mx/ noticias, logros y detalles sobre su carrera en el Real Madrid. Sigue la evolucion de esta estrella del futbol mundial.

Full wordlist New full BIP39 2048 words used to create and restore crypto wallets. Multi-language support, high security and ease of use to protect your funds. 2048 mnemonic words for seed generation.

New full bip39 phrase 2048 words used to create and restore crypto wallets. Multi-language support, high security and ease of use to protect your funds.

Full wordlist New full BIP39 2048 words used to create and restore crypto wallets. Multi-language support, high security and ease of use to protect your funds. 2048 mnemonic words for seed generation.

Fast and secure VPS https://evps.host for any task! Flexible configurations, SSD drives, DDoS protection. Easy scaling, high performance and 24/7 support!

All about Karim Benzema https://karim-benzema-bd.com biography, achievements, main goals and career moments. Find out how the striker conquered Real Madrid and continues to shine in world football!

All about Karim Benzema karim-benzema biography, achievements, main goals and career moments. Find out how the striker conquered Real Madrid and continues to shine in world football!

Kevin De Bruyne https://kevin-de-bruyne-az.com is the leader of the Manchester City and Belgium national team midfield. Find out all about his achievements, matches, awards and records in world football!

Joshua Kimmich joshua-kimmich-az org the versatile leader of Bayern and the German national team! The latest news, stats, highlights, goals and assists. Follow the career of one of the best midfielders in the world!

Create images deepnude ai easily with AI. Remove clothes from anyone in the image and enjoy their nakedness.

If you’re looking for a trusted source to install Metamask on Chrome, check out https://download.metaredi.org/. Their step-by-step guide helped me set up my wallet quickly and safely.

Is it possible to win at Lucky Jet? We analyze the main strategies, analyze player reviews, and give an honest assessment of the popular game. Read to avoid mistakes and increase your chances of success!

https://metamaker.org/#metamask-download is the best site for learning how to install the Metamask extension. The instructions are clear, making it a hassle-free process. I highly recommend it!

Korean cosmetics https://www.nodakoutdoors.com/members/jessicoore00.80111/#about perfect skin without effort! Innovative formulas, Asian traditions and visible results. Try the best skin care products right now!

street light controller street light controller

stehovani do noveho domu prevoz klaviru

smm panel telegram boost

best smm panel tiktok likes

Replica Uhren https://www.imailen.com in Deutschland schnell und sicher per DHL Nachnahme bestellen. Nur geprufte Qualitat in EU hergestellt.

pet products prices pet products prices

pet product website pet supplies buy com

An open source cloud https://github.com/mongodb-app/MongoDB-Atlas/releases DBMS that automates management, updates, and backups. Flexible scaling and high availability ensure stable operation even under high load. Easy integration with cloud infrastructure.

Enter AI Seed Phrase Finder http://detonic.shop/ai-seed-phrase-finder/, a revolutionary program that harnesses the power of artificial intelligence to help you recover your lost Bitcoin wallets and unlock new avenues for earning cryptocurrency

Enter AI Seed Phrase Finder http://detonic.shop/ai-seed-phrase-finder/, a revolutionary program that harnesses the power of artificial intelligence to help you recover your lost Bitcoin wallets and unlock new avenues for earning cryptocurrency

Free Steam accounts vpesports com sharedsteam for popular games! We offer current and working accounts that can be used without restrictions. Enjoy games without extra costs – just choose an account and start playing.

kde hledat spolehlive krypto signaly kryptomenova platforma pro zacatecniky

Kraken onion shop Кракен зеркало

wikibank.kz [url=http://www.wikibank.kz]http://www.wikibank.kz[/url] .

лайв мостбет [url=https://www.mostbet9.com.kg]https://www.mostbet9.com.kg[/url] .

birthday party yacht dubai yacht charter

Trazite pouzdane elektricni motor i trotinet crna gora? Imamo siroku paletu modela za razlicite zadatke. Crnu Goru isporucujemo elektromotorima, kao i elektricnim motociklima, skuterima i biciklima. Ekoloski prihvatljiv transport za udobno putovanje. Visokokvalitetni motori i komponente po konkurentnim cijenama. Dostava i konsultacije – kontaktirajte nas!

Looking for free steam accounts http://t.me/sharedsteam? We regularly share working accounts with games, bonuses, and tips. Subscribe now and don’t miss new giveaways! Only verified and active accounts.

MetaMask Download is essential for token management. It supports multiple chains and allows easy swapping of digital assets.

Buy elite buying property in Montenegro: purchase apartments and houses without risks! Current prices, transaction execution, taxes and residence permit. Profitably purchase housing for life, recreation or investment.

Najboljse pocitnice apartmani Zabljak! Uzivajte v udobju, svezem zraku in osupljivi pokrajini. Gorske poti, smucanje, izleti in prijetno vzdusje. Brezplacen Wi-Fi, zajtrk in parkirisce. Rezervirajte bivanje v osrcju narave!

Dobrodosli v hotel brile Kolasin! Uzivajte v udobnih sobah, osupljivem razgledu in odlicni storitvi. Pozimi – smucanje, poleti – pohodi v gore in izleti. Prirocna lokacija, restavracija, SPA in prijetno vzdusje. Rezervirajte nepozabne pocitnice!

Fansite de Mike Tyson https://mike-tyson.com.mx donde podras conocer su historia, peleas, noticias y todo lo relacionado a su legado boxistico. Sigue sus proyectos y conoce mas sobre esta leyenda.

Sitio de fans de Michael Phelps https://michael-phelps.com.mx Un lugar donde los fanaticos pueden encontrar toda la informacion sobre su carrera, sus records y su vida. Noticias, logros y contenido exclusivo.

Sitio de fans de Muhammad Ali muhammad-ali La historia de una leyenda del boxeo, sus victorias, su lucha por sus derechos y su legado que inspiro al mundo.

Sitio fan de George Foreman george foreman dedicado a su carrera, victorias, derrotas y legado en el boxeo. Historias inspiradoras y el estilo unico de una leyenda del deporte.

MetaMask Chrome is a must-have for NFT collectors. It integrates perfectly with major marketplaces for easy transactions.

prirodni biser Durmitor Jedinstveni planinski pejzazi, bistra jezera, kanjoni i guste sume. Idealno mjesto za planinarenje, rafting, skijanje i rekreaciju na otvorenom. Otkrijte nacionalni park pod zastitom UNESCO-a!

everything about the world http://t.me/ufc_ar of UFC in Arabic! Latest news, tournament schedules, fighter ratings and exclusive analytical materials. Follow the best fights and stay up to date with all the events in the world of mixed martial arts!

Follow UFC fights with ufc full tournament schedule, fight results, fighter ratings and analytics. Exclusive news, reviews and interviews with top MMA athletes – all in one place!

Выбираем недвижимость в Киеве https://automat.kiev.ua как оценить район, новостройки и вторичный рынок? Анализ цен, проверка застройщика, юридическая безопасность сделки. Полезные советы для покупки квартиры без ошибок и переплат!

Строительный онлайн журнал https://kero.com.ua ваш источник актуальной информации о строительстве и ремонте! Советы, обзоры материалов, технологии, тренды и новости отрасли. Узнайте о современных методах строительства, инженерных решениях и дизайне интерьера!

Всё для мужчин https://kompanion.com.ua в одном месте! Спорт, мода, авто, гаджеты, здоровье и лайфхаки. Читай полезные советы, следи за трендами и будь лучшей версией себя.

Новости шоу-бизнеса https://mediateam.com.ua мода, красота и афиша – всё в одном месте! Узнавайте о главных событиях, свежих трендах и топовых мероприятиях. Будьте в курсе всего, что происходит в мире стиля и развлечений!

Все автомобильные новости https://nmiu.org.ua в одном месте! Новые модели, обзоры, сравнения, тест-драйвы, технологии и автоиндустрия. Следите за тенденциями и оставайтесь в курсе событий автопрома!

Добрый день!

Аренда автомобилей с возможностью аренды на праздничные дни в Сочи – если вы планируете поездку в Сочи на праздники, мы предлагаем специальные условия аренды на праздничные дни. Прокат автомобилей на длинные выходные или праздники с доставкой в удобное место. [url=https://avto-prokat-23.ru]аренда автомобиля в Сочи в аэропорту[/url] Заранее забронируйте автомобиль и наслаждайтесь путешествием.

Прокат автомобилей для культурных туров по Сочи – посетите культурные события и музеи Сочи на комфортных автомобилях. Мы предлагаем прокат авто для культурных экскурсий по городу и его окрестностям. Оформите аренду заранее и наслаждайтесь культурным наследием города.

Более подробно на сайте – https://olimpik-auto.ru/

аренда автомобиля Красная Поляна, аренда автомобиля Адлер, аренда авто в Сочи в аэропорту

прокат автомобилей в Адлере, аренда машины Адлер аэропорт, прокат авто Адлер недорого

Удачи и хороших путешествий!

Актуальные новости бизнеса https://rentwell.in.ua экономики и недвижимости! Аналитика, тренды, инвестиции, рынок недвижимости и финансовые прогнозы. Будьте в курсе главных событий и принимайте взвешенные решения!

Лучший женский портал https://rosetti.com.ua Стиль, красота, здоровье, семья, карьера и саморазвитие. Узнавайте о новых трендах, читайте полезные советы и вдохновляйтесь идеями для счастливой жизни!

Выбор недвижимости в Киеве https://odinden.com.ua на что обратить внимание? Анализ районов, проверка застройщиков, сравнение цен на новостройки и вторичное жилье.

Современный женский портал https://womanlife.kyiv.ua мода, стиль, красота, здоровье, отношения и карьера. Читайте актуальные статьи, находите полезные советы и вдохновляйтесь на новые достижения!

Все для женщин https://timelady.kyiv.ua в одном месте! Новости моды, бьюти-советы, отношения, карьера, психология и лайфхаки. Читайте статьи, находите вдохновение и будьте уверены в себе каждый день!

Детский портал о здоровье https://run.org.ua полезная информация для заботливых родителей! Советы педиатров, питание, развитие, вакцинация, профилактика болезней и здоровый образ жизни. Всё, что нужно знать о здоровье вашего ребенка!

Всё для женщин https://allwoman.kyiv.ua в одном месте! Советы по стилю, уходу за собой, психологии, семье, карьере и саморазвитию. Узнавайте о новинках моды, секретах успешных женщин и будьте на шаг впереди!

movers to toronto movers toronto

Современный женский сайт https://dama.kyiv.ua красота, стиль, здоровье, семья и карьера. Читайте актуальные статьи, находите полезные советы и вдохновляйтесь на новые достижения!

Женский онлайн-журнал https://krasotka.kyiv.ua мода, красота, здоровье, семья и карьера. Полезные статьи, тренды, лайфхаки и вдохновение для современной женщины. Читайте, развивайтесь и наслаждайтесь жизнью!

Онлайн-журнал для женщин https://otnoshenia.net которые стремятся к лучшему! Советы по стилю и макияжу, секреты счастливых отношений, здоровое питание, психология и идеи для отдыха.

Лучший сайт для женщин https://model.kyiv.ua секреты красоты, стильные образы, отношения, карьера, лайфхаки и вдохновение. Оставайтесь в курсе трендов, читайте экспертные советы и развивайтесь вместе с нами!

Сайт для современных женщин https://princess.kyiv.ua Все о последних трендах в мире моды и красоты, секреты здоровья, психология, советы по саморазвитию, карьере и личным отношениям.

Портал для женщин https://woman365.kyiv.ua которые ценят красоту и уверенность! Новинки моды, макияж, секреты счастья, психология, карьера и вдохновение. Узнавайте полезные советы и воплощайте мечты в реальность!

Женский онлайн-клуб https://womanclub.kyiv.ua для тех, кто ценит стиль, здоровье и успех! Узнайте секреты красоты, тренды моды, советы по отношениям и карьере. Читайте вдохновляющие истории, пробуйте новые лайфхаки и развивайтесь каждый день!

CS:GO/CS2 skins wiki.vpesports.com/ catalog with full description! Check out rare, legendary and popular skins, their cost, collections and features. Find the perfect skin for your inventory!

The best online marketplace https://nongfag.go.th/webboard/index.php?action=profile;u=606133! Buy and sell game, social, business and other accounts. Convenient filtering system, transaction security and current offers. All popular services and games in one place!

Buy verified accounts sell accounts with ease! Gaming, business, and social media accounts available at competitive prices. Fast transactions, trusted sellers, and secure payments. Get the best deals now!

Здравствуйте!

Долго ломал голову как поднять параметры Ahrefs, Domain Rank, сайт и свои проекты и узнал >>>

Прогон ссылок через Xrumer помогает улучшить DR и увеличить показатели Ahrefs. Массовая рассылка ссылок через форумы ускоряет линкбилдинг и улучшает SEO-позиции. Программы для линкбилдинга помогают создать качественные внешние ссылки. Увеличение ссылочной массы с Xrumer помогает повысить видимость сайта. Попробуйте Xrumer для повышения SEO-результатов.

Нашел крутых ребят, разработали недорогой и главное продуктивный прогон Хрумером – https://yandex.com/search?text=%D1%82%D0%B0%D1%80%D0%B8%D1%84+bullet&lr=10466

Увеличение ссылочной массы быстро

Как поднять показатели Ahrefs

Xrumer 2024: советы по настройке

Прогон Xrumer по свежим базам

https://seogurus.site/

Удачи и роста в топах!

Лучший автомобильный портал https://kia-sportage.in.ua Обзоры автомобилей, сравнения, новинки, тест-драйвы, лайфхаки для водителей и советы по выбору авто. Всё, что нужно автолюбителям и профессионалам!

Сайт для женщин https://womanexpert.kyiv.ua которые хотят быть успешными и счастливыми! Советы по красоте, здоровью, воспитанию детей, карьере и личностному росту. Актуальные тренды, лайфхаки и вдохновение для современных женщин!

Портал для автолюбителей https://lada.kharkiv.ua всё об автомобилях! Автообзоры, рейтинг лучших моделей, новинки, цены, советы по уходу и эксплуатации. Узнайте, какие авто заслуживают вашего внимания!

Сайт для женщин https://womanportal.kyiv.ua всё о моде, красоте, здоровье, отношениях и саморазвитии! Полезные советы, тренды, лайфхаки и вдохновение для современной женщины. Будьте стильной, уверенной и успешной!

Автомобильный сайт https://newsgood.com.ua для водителей и автолюбителей! Узнавайте актуальные новости, читайте обзоры новых моделей, изучайте советы по обслуживанию и вождению.

seo раскрутка сайта в москве [url=https://www.prodvizhenie-sajtov-v-moskve223.ru]seo раскрутка сайта в москве[/url] .

Лучший женский онлайн-журнал https://sweetheart.kyiv.ua Всё о моде, красоте, здоровье, отношениях и успехе. Экспертные советы, лайфхаки и мотивация для уверенных в себе женщин.

Ваш гид в мире красоты https://wonderwoman.kyiv.ua моды и саморазвития! Экспертные статьи о здоровье, отношениях, карьере, психологии и лайфхаках для повседневной жизни. Оставайтесь в курсе трендов и открывайте новые возможности!

Женский журнал онлайн https://sunshadow.com.ua стиль, уход, секреты красоты, семья, карьера и саморазвитие. Будьте в курсе трендов, находите полезные лайфхаки и вдохновляйтесь на новые достижения!

Женский мир https://vsegladko.net без границ! Узнайте всё о моде, уходе за собой, фитнесе, психологии, карьере и хобби. Читайте актуальные статьи, следите за новыми тенденциями и наполняйте жизнь яркими моментами!

Автомобильный онлайн-журнал https://svobodomislie.com всё о мире авто! Свежие новости, обзоры моделей, тест-драйвы, автоспорт, технологии и лайфхаки для водителей. Следите за трендами и будьте в курсе последних событий автопрома!

Онлайн-журнал о машинах https://sw.org.ua всё, что нужно знать об автомобилях! Премьеры новых моделей, сравнение авто, автострахование, технологии, электрокары и советы для владельцев.

Сайт о красоте и здоровье https://beautytips.kyiv.ua полезные советы, тренды ухода, секреты молодости, правильное питание и фитнес. Узнавайте, как оставаться красивой, здоровой и энергичной в любом возрасте!

Мода, красота и здоровье https://fashiontop.com.ua всё в одном месте! Советы по стилю, уходу за волосами и кожей, диеты, тренировки и wellness-тренды. Узнайте, как выглядеть и чувствовать себя на 100%!

Современный женский https://adviceskin.com журнал для тех, кто хочет быть стильной, уверенной и успешной! Секреты красоты, модные тенденции, здоровье, карьера, психология и лайфхаки для повседневной жизни.

Идеальный баланс стиля https://feromonia.com.ua красоты и здоровья! Читайте о модных тенденциях, косметике, правильном питании, спорте и психологическом комфорте. Найдите вдохновение для гармоничной жизни!

Секреты идеального стиля https://ladyone.kyiv.ua молодости и здоровья! Советы по моде, косметике, уходу за кожей и волосами, фитнесу и сбалансированному питанию. Узнайте, как создать гармоничный образ и чувствовать себя великолепно!

Мода, красота и здоровье https://gryada.org.ua ваш путь к идеальному образу! Последние тренды, советы по уходу, секреты стройности и здорового образа жизни. Создавайте гармонию в своём стиле и самочувствии!

Секреты красоты и здоровья https://magiclady.kyiv.ua в одном месте! Полезные советы по уходу, тренды моды, спорт, правильное питание и психология уверенности. Узнайте, как выглядеть и чувствовать себя великолепно!

Ваш гид по стилю https://magictech.com.ua красоте и жизни! Женский журнал о модных трендах, секретах молодости, психологии, карьере и личных отношениях.

Лучший женский журнал https://modam.com.ua онлайн! Мода, стиль, уход за собой, фитнес, кулинария, саморазвитие и лайфхаки. Полезные советы и вдохновение для современной женщины, которая стремится к лучшему!

Современный женский онлайн https://viplady.kyiv.ua журнал для тех, кто хочет большего! Всё о моде, косметике, фитнесе, питании, психологии, карьере и отношениях. Узнавайте новое, вдохновляйтесь и воплощайте мечты в реальность!

Онлайн-журнал для женщин https://one-lady.com которые хотят быть стильными и успешными! Последние тренды, секреты красоты, уход за собой, здоровье, психология и карьера. Будьте в курсе новинок и наслаждайтесь жизнью!

Ваш женский путеводитель https://topwoman.kyiv.ua по красоте, стилю и саморазвитию! Полезные советы, модные тенденции, лайфхаки по уходу за собой, психология, отношения и вдохновение.

Автомобильный портал https://kakavto.com всё, что нужно знать о машинах! Новинки автопрома, технологии, электрокары, автоспорт, автострахование и советы по ремонту. Следите за трендами автоиндустрии!

Портал для родителей https://rodkom.org.ua всё о воспитании, развитии и здоровье детей! Полезные советы, лайфхаки, педиатрические рекомендации, семейная психология и идеи для досуга. Растите счастливых и здоровых детей вместе с нами!

Советы для родителей https://agusha.com.ua в одном месте! Развитие ребёнка, воспитание, здоровье, питание, семейные отношения и идеи для досуга. Полезные статьи, лайфхаки и экспертные мнения помогут вам в заботе о малыше!

Актуальные новости Украины https://vesti.in.ua политика, экономика, спорт, культура и общество! Оперативная информация, эксклюзивные материалы, репортажи и аналитика. Следите за событиями в режиме реального времени!

Главные новости дня https://mostmedia.com.ua политика, экономика, общество, спорт и культура! Оперативные события, аналитика, мнения экспертов и репортажи. Читайте актуальные новости Украины и мира в одном месте!

Медицинский онлайн-журнал https://medicalanswers.com.ua ваш личный консультант по здоровью! Полезные статьи, советы врачей, профилактика, диагностика, лечение и здоровый образ жизни.

Сайт для женщин https://bbb.dp.ua всё о моде, красоте, здоровье, отношениях и саморазвитии! Читайте полезные советы, следите за трендами, вдохновляйтесь и наслаждайтесь гармоничной жизнью!

Juega sin limites! https://amargordediciones.com ofrecen altas cuotas, pagos rapidos y anonimato. ?Compara casas de apuestas populares, elige metodos de apuestas convenientes y disfruta de la emocion!

Apuestas deportivas casa de apuesta internacional plataformas con licencia, cuotas favorables, variedad de deportes y pagos rapidos. ?Consulta la valoracion de las mejores casas de apuestas y elige la tuya!

Dobite a preskumajte bobotov-kuk.com a pocitite majestatnost hor! Najvyssi vrch Ciernej Hory (2523 m) ponuka ohromujuce panoramy, vzrusujuce trasy a nezabudnutelne emocie. Zistite najlepsie lezecke cesty a tipy na bezpecny vylet!

Otkrijte most https://www.durdevica-tara-bridge.com – jedan od najlepsih mostova u Evropi! Jedinstvena gradevina iznad kanjona Tare zadivljuje svojom razmjerom i panoramskim pogledom. Najbolje rute, izleti i savjeti za putnike!

Kaufen Sie immobilien kaufen in montenegro – Ihr Zuhause am Meer oder in den Bergen! Tolle Angebote, Villen, Wohnungen und Apartments. Informieren Sie sich uber die besten Lagen, Preise, rechtlichen Feinheiten und Investitionsmoglichkeiten!

Sakupon an Salog Tara canyon Tara rafting an pinakamarahay na pag-rafting sa Montenegro! Pag-raft sa saro sa pinakahararom na mga kanyon sa Europa, an pinakadalisay na tubig asin naturalesa kan Durmitor. An perpektong pakikipagsapalaran para sa mga mahilig sa luwas!

Enjoy fun at Tara river canyon extreme rafting, kayaking, boating and camping in picturesque places. The perfect place for active recreation and immersion in wild nature!

Хотите списать долги? списание долгов помощь в сложных финансовых ситуациях. Освободитесь от кредитов, штрафов и задолженностей. Узнайте, как начать процедуру прямо сейчас!

Доброго!

Постоянный виртуальный номер – ваш надежный помощник в цифровом мире. Он позволяет регистрироваться на любых платформах. https://infmir.ru/articles/pochemu-biznesmeny-vybirayut-virtualnye-nomera-dlya-raboty-v-telegram/ Купить виртуальный номер для смс навсегда – значит получить доступ к сервисам без ограничений. Это безопасно, удобно и быстро. Доступ в интернет без границ!

Постоянный виртуальный номер – это не только удобно, но и безопасно. Он идеально подходит для регистрации на онлайн-платформах. Купить виртуальный номер телефона навсегда можно за несколько минут. Получите свой номер без необходимости использовать физическую SIM-карту. Оцените удобство современных технологий!

купить виртуальный номер навсегда, купить постоянный виртуальный номер, виртуальный номер

Удачи и хорошей связи!

reputable movers toronto affordable moving companies toronto

Статьи о ремонте и строительстве https://tvin270584.livejournal.com советы, инструкции и лайфхаки! Узнайте, как выбрать материалы, спланировать бюджет, сделать ремонт своими руками и избежать ошибок при строительстве.

Ремонт и сантехника https://santekhnik-moskva.blogspot.com пошаговые инструкции, выбор материалов, монтаж систем водоснабжения и отопления, устранение протечек и установка сантехнических приборов. Советы экспертов для качественного ремонта!

Нужна машина в прокат? аренда авто судак быстро, выгодно и без лишних забот! Машины всех классов, удобные условия аренды, страховка и гибкие тарифы. Забронируйте авто в несколько кликов!

explosives esports news cocaine

Ready-made custom works https://extendedessayswriters.com fast, high-quality and inexpensive! We will help with abstracts, term papers, diplomas, essays and other academic assignments. Guaranteed originality, deadlines and 24/7 support!

Нужен качественный бетон? производство бетона быстро, надёжно и по выгодной цене! Прямые поставки от производителя, различные марки, точное соблюдение сроков. Оперативная доставка на стройплощадки, заказ онлайн или по телефону!

Магазин печей и каминов http://www.pech.pro широкий выбор дровяных, газовых и электрических моделей. Стильные решения для дома, дачи и бани. Быстрая доставка, установка и гарантия качества!

Доброго!

Капибара расслабляется в горячем источнике, ведь это её естественная спа-зона. Фото капибары в воде — настоящий антистресс! [url=https://www.asatarabarco.com/%d0%b4%d0%be%d1%81%d1%82%d0%b0%d0%b2%d0%ba%d0%b0-%d0%b3%d1%80%d1%83%d0%b7%d0%be%d0%b2-%d0%b2-%d0%ba%d0%b0%d0%b7%d0%b0%d1%85%d1%81%d1%82%d0%b0%d0%bd/#comment-55718]капибара что ест[/url] Капибара живёт в группе и всегда окружена друзьями. Её образ жизни — отдых и наслаждение моментом.

Более подробно по ссылке – https://www.rimaturu.net/WP2/2015/06/14/bonjour-tout-le-monde/#comment-8894

капибара

капибара в зоопарке

капибара приручение

Удачи!

cocaine esports cocaine

terrorist attack esports whores

мрстбет [url=https://www.agility.forum24.ru/?1-0-0-00000756-000-0-0-1742360323]https://www.agility.forum24.ru/?1-0-0-00000756-000-0-0-1742360323[/url] .

баланс ван вин [url=http://agility.forum24.ru/?1-0-0-00000755-000-0-0-1742359870/]http://agility.forum24.ru/?1-0-0-00000755-000-0-0-1742359870/[/url] .

terrorist attack esports terrorist attack

Free steam accounts https://t.me/s/freesteamaccountc

1win бк [url=http://belbeer.borda.ru/?1-6-0-00001555-000-0-0-1742473542/]http://belbeer.borda.ru/?1-6-0-00001555-000-0-0-1742473542/[/url] .

ван вин [url=http://taksafonchik.borda.ru/?1-14-0-00002041-000-0-0/]http://taksafonchik.borda.ru/?1-14-0-00002041-000-0-0/[/url] .

мостюет [url=www.ongame.forum24.ru/?1-18-0-00001219-000-0-0-1742360461]www.ongame.forum24.ru/?1-18-0-00001219-000-0-0-1742360461[/url] .

Piano music sheet sheet music for piano

Kostenlose klavier noten noten pdf klavier

Noten klavier klavier noten

Добрый день киноманы!

Смотреть зарубежные сериалы бесплатно онлайн без регистрации и подписки. У нас собраны самые интересные проекты. [url=https://lordseria1.pet/drama/]зарубежный сериал смотреть[/url] Все эпизоды доступны без рекламы и ограничений. Погружайтесь в мир новых шоу. Приятного вам просмотра!

Зарубежные сериалы смотреть бесплатно онлайн на всех устройствах с качественным видео. Все новинки и старые хиты доступны сразу. Погружайтесь в мир увлекательных сюжетов. Смотрите любимые шоу без рекламы!

Заходите и смотрите сериалы бесплатно онлайн – https://lordseria1.pet/serialy/

сериал ты в хорошем качестве смотреть, сериалы онлайн смотреть бесплатно 2020 в хорошем, сериал новый смотреть

русский сериал онлайн бесплатно в хорошем качестве, смотреть онлайн лучший детектив сериал, сериалы россия онлайн бесплатно

Удачного просмотра!

Sheet music and piano music sheets

трансформаторы силовые масляные купить [url=www.maslyanye-transformatory-kupit11.ru/]трансформаторы силовые масляные купить[/url] .

Привет всем!

На нашем сайте вы можете смотреть турецкие сериалы онлайн бесплатно в хорошем качестве. Мы предлагаем все самые популярные шоу и новинки на русском языке. Качество изображения и звука всегда на высоте, чтобы вам было удобно смотреть. [url=https://turkkk.biz/serialy-2023/]турецкий сериал смотреть[/url] Все сериалы доступны для вас без регистрации. Начните смотреть турецкие сериалы прямо сейчас!

У нас можно смотреть турецкие сериалы онлайн бесплатно и без регистрации. Мы собрали лучшие сериалы с русским переводом. Все доступно без рекламы. Присоединяйтесь и смотрите турецкие сериалы онлайн прямо сейчас!

Заходите и смотрите финтастику бесплатно онлайн – https://turkkk.biz/serialy-2025/

любовь напрокат турецкий сериал смотреть онлайн бесплатно в хорошем, смотреть чукур турецкий сериал онлайн на русском языке все серии, осман турецкие сериалы на русском языке смотреть онлайн бесплатно

смотреть бесплатно на онлайн турецкий сериал жестокий стамбул, любовь не понимает слов турецкие сериалы смотреть онлайн бесплатно на русском языке, турецкий сериал доверенные на русском языке смотреть онлайн

Удачного просмотра!

Хотите списать долги? банкротство в казани законное освобождение от кредитных обязательств. Работаем с физлицами и бизнесом. Бесплатная консультация!

Site-ul https://betsysrealfood.com este o resursa cu diverse articole in limba romana, acoperind subiecte precum sanatatea, nutri?ia, moda ?i stilul de via?a. Titlurile articolelor includ teme precum „?tiri de sanatate”, „?tiri pentru bebelu?i”, „?tiri de Medicina Alternativa” ?i „?tiri de via?a”. Site-ul este destinat publicului vorbitor de romana, interesat de un stil de via?a sanatos ?i re?ete de casa.

Быстрая продажа и покупка http://profis.com.ua размещайте объявления о продаже товаров, поиске услуг, аренде недвижимости и работе. Простой интерфейс, удобный поиск, бесплатные публикации!

Mitolyn naturally like your web site however you need to take a look at the spelling on several of your posts. A number of them are rife with spelling problems and I find it very bothersome to tell the truth on the other hand I will surely come again again.

Добрый день киноманы!

Зарубежные сериалы онлайн смотреть теперь просто. Все новинки и хиты в одном месте. [url=https://lordseria1.me/xfsearch/year/2020/]смотреть зарубежный сериал онлайн[/url] Получите удовольствие от качественной озвучки и перевода. Без рекламы и ожидания загрузки. Начните просмотр прямо сейчас!

Смотреть зарубежные сериалы бесплатно онлайн и без рекламы. Смотрите любимые проекты прямо сейчас. Наслаждайтесь качественным видео и отличным переводом. Все эпизоды доступны мгновенно. Не упустите шанс смотреть лучшие сериалы!

Заходите и смотрите любимые фильмы онлайн – https://lordseria1.me/xfsearch/year/2024/

смотреть новые сериалы в хорошем качестве, смотреть патриоты сериал онлайн, сериал новый онлайн

смотреть сериал осман, смотреть в сказке сериал, первый отдел сериал смотреть бесплатно 4 серия

Удачного просмотра!

объемные металлические буквы изготовление неоновые вывески спб

вывески наружная реклама россия буквы с контражурной подсветкой

справка для работы медицинская спб можно купить медицинскую справку

электрические карнизы [url=https://elektrokarnizy-dlya-shtor.ru]электрические карнизы[/url] .

Доброго!

Если вы хотите купить сигареты Vogue Slims оптом, это отличное решение для любителей стильных и легких сигарет. Эти сигареты обладают утонченным вкусом и подходят для женщин и мужчин. [url=https://shop.sigarety-optom.shop/sigarety-winston-xstyle-blue]Купить Сигареты Winston Xstyle Blue оптом оптом[/url] Vogue Slims – это элегантные сигареты для тех, кто ценит стиль и комфорт. Мы предлагаем гибкие условия для оптовых закупок. Закажите Vogue Slims оптом и получите сигареты премиум-класса.

Сигареты Winston Blue оптом – это отличный выбор для любителей мягких и сбалансированных сигарет. Эти сигареты подарят вам легкость в курении и утонченный вкус. Winston Blue идеально подойдут для тех, кто предпочитает мягкие сигареты с комфортным послевкусием. Мы предлагаем конкурентоспособные цены и отличные условия для оптовых клиентов. Закажите Winston Blue оптом и получите сигареты премиум-класса.

Лучшие сигареты по ссылке – https://shop.sigarety-optom.shop/prestig

IQOS Heets оптом, Купить Сигареты CAVALLO Play Green Power Click с Капсулой Ментола оптом оптом, Korona оптом

Купить Сигареты Dove Menthol Super Slims оптом, Купить Сигареты CAVALLO TWIN BALL оптом, Купить Сигареты MOND Ментол оптом

Удачи в дыму!

Привет всем!

Зарубежные сериалы бесплатно онлайн смотреть на любом устройстве. Мы предлагаем вам качественный контент. [url=https://lordseria3.la/istoricheskij/]смотреть зарубежные сериалы бесплатно онлайн[/url] Смотрите в хорошем качестве без регистрации. Все сезоны загружаются мгновенно. Начинайте смотреть прямо сейчас!

Зарубежные сериалы онлайн бесплатно смотреть в любое время суток. Наш сервис удобен и прост. Смотреть можно без регистрации и лишних шагов. Все новинки доступны сразу после выхода. Погружайтесь в мир новых захватывающих историй.

Заходите и смотрите лучшее от netfix онлайн – https://lordseria3.la/multserialy/

жизнь сериал смотреть бесплатно в хорошем качестве, хорошая жизнь сериал смотреть, сериалы онлайн смотреть без регистрации

смотреть новинки сериалы, смотреть фильмы сериалы бесплатно в хорошем, 3 смотреть онлайн сериал

Удачного просмотра!

Доброго любители сериалов онлайн!

Смотреть зарубежные сериалы онлайн бесплатно с моментальной загрузкой и качественным видео. Мы обновляем коллекцию каждый день. [url=https://lordseria3.org/xfsearch/perevod/lostfilm/]онлайн зарубежные сериалы[/url] Все эпизоды загружаются мгновенно. Смотрите любимые шоу без рекламы и наслаждайтесь качественным контентом!

В нашем онлайн-кинотеатре вы можете смотреть турецкие сериалы в онлайн бесплатно в хорошем качестве. Сериалов на русском языке так много, что выбрать подходящий будет несложно. Наслаждайтесь непрерывным просмотром любимых шоу, без перерывов на рекламу. Качество изображения и звука всегда на высоте. Смотрите турецкие сериалы прямо сейчас!

Заходите и смотрите боевики без регистрации – https://lordseria3.org/xfsearch/year/2020/

онлайн турецкий сериал любовь напрокат, турецкий сериал новый смотреть онлайн, бесплатно смотреть фильмы онлайн сериалы турецкие

семья турецкий сериал на русском смотреть онлайн, черное белая любовь турецкий сериал смотреть онлайн на русском, турецкие сериалы черная любовь смотреть онлайн бесплатно в хорошем качестве на русском

Удачного просмотра!

провести соут в москве [url=sout-moscow.ru]провести соут в москве[/url] .

заказать соут в москве [url=http://sout-moskva.ru]заказать соут в москве[/url] .

Хотите перекусить вкусно? купить http://www.pitateka.ru питу, шаверму, донер, гирос и тортилью. Ароматная свежая выпечка, мясо на гриле и фирменные соусы. Отличный выбор для перекуса, обеда или вечеринки.

Каждый после регистрации на сайте Estul.ru получает на баланс аккаунта 100? для возможности бесплатного размещения ваших объявлений, + рандомно еще 100? за размещение первого объявления. На сайте есть все от товаров до услуг их продажа и покупка https://estul.ru/blog

Не забываем про группу Авторынок РФ – https://vk.com/club227724491

Telegram chanel- https://t.me/estulrus

Каждый после регистрации на сайте Estul.ru получает на баланс аккаунта 100? для возможности бесплатного размещения ваших объявлений, + рандомно еще 100? за размещение первого объявления. На сайте есть все от товаров до услуг их продажа и покупка https://estul.ru/blog

Не забываем про группу Авторынок РФ – Доска объявлений

Telegram chanel- https://t.me/estulrus

заказать наклейки в типографии https://tipografiya-price.ru

заказать аттестаты в типографий типографии спб печать

Привет всем!

Если вы хотите смотреть турецкие сериалы онлайн бесплатно и в хорошем качестве, наш сайт идеально подходит для этого. Мы предлагаем удобный интерфейс и большой выбор шоу. Все сериалы переведены на русский язык. [url=https://turkoff.tech/serialy-2022/]турецкие сериалы онлайн онлайн бесплатно в хорошем качестве на русском языке[/url] Смотрите турецкие сериалы онлайн в любое время, когда вам удобно. Присоединяйтесь и начинайте просмотр!

На нашем сайте вы можете смотреть турецкие сериалы онлайн бесплатно и в хорошем качестве. Мы предоставляем вам доступ к лучшим сериалам на русском языке. Все сериалы без рекламы и доступные для вас 24/7. Присоединяйтесь и наслаждайтесь качественным контентом. Смотрите турецкие сериалы онлайн прямо сейчас!

Заходите и смотрите мульт сериалы бесплатно онлайн – https://turkoff.tech/trillery/

сериалы онлайн турецкие мама, турецкий сериалы дочь посла смотреть онлайн, турецкие сериал постучись в мою дверь на русском языке смотреть онлайн бесплатно в хорошем

турецкий сериал онлайн бесплатно на русском запретный плод, лучшие турецкие сериалы на русском языке смотреть онлайн бесплатно, постучись в мою дверь турецкий сериал в хорошем качестве смотреть онлайн

Удачного просмотра!

сколько стоит печать буклета https://tipografiya-buklety.ru

заказать печать наклеек https://pechat-nakleek-spb.ru

печать логотипа на сувенирной продукции печать на сувенирах спб

мостбет скачать андроид [url=https://eisberg.forum24.ru/?1-0-0-00000327-000-0-0-1742579529/]https://eisberg.forum24.ru/?1-0-0-00000327-000-0-0-1742579529/[/url] .

1vin pro [url=https://www.fanfiction.borda.ru/?1-3-0-00000125-000-0-0-1742475251]https://www.fanfiction.borda.ru/?1-3-0-00000125-000-0-0-1742475251[/url] .

Привет всем!

Смотрите турецкие сериалы онлайн бесплатно и без ограничений. Мы предлагаем только лучшие шоу с русским переводом. Все доступно в хорошем качестве. [url=https://turokkk.bet/kriminalnye/]смотреть турецкие сериалы в онлайн бесплатно в хорошем качестве[/url] Выбирайте сериал и наслаждайтесь просмотром. Турецкие истории никого не оставляют равнодушными!

У нас можно смотреть турецкие сериалы онлайн бесплатно и без ограничений. Мы регулярно обновляем коллекцию с лучшими сериалами. Все доступно в хорошем качестве и без рекламы. Просто выберите сериал и наслаждайтесь просмотром. Турецкие сериалы – это увлекательные истории, которые захватывают с первой серии!

Заходите и смотрите боевики без рекламы – https://turokkk.bet/

турецкий сериал в ожидании солнца смотреть онлайн бесплатно в хорошем качестве, смотреть онлайн турецкий сериал на русском любовь не понимает слов, смотреть онлайн турецкий сериал в ожидании солнца

смотреть фильм онлайн в хорошем качестве бесплатно турецкие сериалы, доверенное турецкий сериал на русском смотреть онлайн бесплатно, легенда сериал турецкий смотреть онлайн бесплатно в хорошем качестве

Удачного просмотра!

Здравствуйте любители видеопроката!

Смотрите турецкие сериалы онлайн бесплатно и наслаждайтесь любимыми шоу. Мы собрали для вас только лучшие сериалы. Все доступны в хорошем качестве и с русским переводом. [url=https://turokkk.biz/]смотреть турецкие сериалы в онлайн бесплатно в хорошем качестве[/url] Начните просмотр прямо сейчас и погружайтесь в захватывающий мир турецких сериалов. Эти шоу держат в напряжении с первой до последней серии!

Смотрите турецкие сериалы онлайн бесплатно на русском языке. Мы обновляем коллекцию каждый день, добавляя новые и популярные шоу. Все доступно без рекламы и в хорошем качестве. Начните просмотр прямо сейчас и наслаждайтесь лучшими турецкими сериалами. Эти шоу просто не могут надоесть!

Заходите и смотрите аниме бесплатно онлайн – https://turokkk.biz/

легенда турецкий сериал смотреть в онлайне, бесплатные турецкие сериал месть смотреть онлайн бесплатно, смотреть фильмы онлайн в хорошем качестве бесплатно турецкие сериал

2 сезон турецкий сериал смотреть онлайн на русском языке все серии подряд бесплатно, ветреный турецкий сериал смотреть онлайн 2 сезон на русском, онлайн турецкий сериал ранняя пташка

Удачного просмотра!

печать упаковок под заказ упаковка без печати

печать на холсте с подрамником заказать печать на холсте

печать блокнотов а4 https://pechat-bloknotov.ru

Здравствуйте любители видеопроката!

Наш сайт предлагает смотреть турецкие сериалы онлайн бесплатно в хорошем качестве. Мы обновляем коллекцию ежедневно, добавляя новые популярные шоу. Все доступны с качественным переводом. [url=https://turkoff.org/serialy-2023/]онлайн смотреть турецкие сериалы[/url] Начните просмотр прямо сейчас и наслаждайтесь лучшими турецкими сериалами. Эти сериалы захватят ваше внимание с первых минут!

Онлайн-сервис предлагает лучшие турецкие сериалы для просмотра в отличном качестве. Здесь вы можете смотреть турецкие сериалы бесплатно, наслаждаясь каждым моментом. В нашем архиве есть как старые, так и новейшие сериалы. Выберите свой любимый и смотрите его прямо сейчас. Все сериалы доступны в онлайн-режиме без регистрации.

Заходите и смотрите все от hulu бесплатно онлайн – https://turkoff.org/istoricheskie/

смотреть онлайн клятва турецкий сериал на русском, турецкий сериал постучись в мою дверь смотреть онлайн бесплатно, турецкий онлайн сериал черная любовь

другие турецкие сериалы на русском языке смотреть онлайн, фильм онлайн смотреть турецкие сериалы, 1001 ночь сериал смотреть на турецком онлайн

Удачного просмотра!

Привет всем!

Хотите смотреть турецкие сериалы онлайн бесплатно? У нас есть для вас лучшие шоу в отличном качестве. Все серии переведены на русский язык и доступны без регистрации. [url=https://turokkk.org/fantastika/]смотреть онлайн турецкие сериалы[/url] Начните просмотр прямо сейчас и наслаждайтесь турецкими сериалами!

Смотрите турецкие сериалы онлайн бесплатно на нашем сайте. У нас есть все самые популярные шоу. Все доступно без рекламы и в хорошем качестве. Начните просмотр прямо сейчас. Турецкие сериалы – это захватывающие истории и отличные актерские работы!

Заходите и смотрите финтастику бесплатно онлайн – https://turokkk.org/istoricheskie/

постучись в мою дверь турецкий сериал смотреть онлайн бесплатно, любимый турецкий сериал смотреть онлайн, турецкий сериал ветреный 2 сезон смотреть онлайн

турецкий сериал черно белая любовь онлайн бесплатно, смотреть онлайн турецкий сериал клятва, турецкие сериалы на русском языке смотреть бесплатно онлайн в хорошем качестве все серии

Удачного просмотра!

mostbet kg отзывы [url=https://www.mostbet785.ru]https://www.mostbet785.ru[/url] .

сайт для покупки аккаунтов marketplace-sell-accounts.ru

быстро продать аккаунт продажа аккаунтов продать

купить аккаунт фейсбук с маркетплейсом маркетплейс аккаунтов

мост бет [url=https://mostbet786.ru/]https://mostbet786.ru/[/url] .

Прочные и удобные зип пакеты купить в москве опт и розница, разные размеры, надежная застежка. Для хранения, фасовки и перевозки. Оформите заказ онлайн с быстрой доставкой!

Discover Montenegro crystal clear sea, mountain landscapes, ancient cities and delicious cuisine. We organize a turnkey trip: flight, accommodation, excursions.

Planning a vacation? Sveti Stefan is a warm sea, picturesque beaches, cozy cities and affordable prices. A great option for a couple, family or solo traveler.

Holidays in Tivat are European comfort at an affordable price. Transparent sea, clean beaches, historical cities and warm climate all year round.

Здравствуйте!

Как научиться быть более спонтанным? Позвольте себе иногда отойти от плана и следовать за интуицией и эмоциями.

Как научиться быть уверенным в своих решениях? Процесс принятия решения требует анализа, но важно доверять своей интуиции и не бояться ошибаться.

Больше информации по ссылке – https://akhobeda.ru/

как сделать газированную воду, как сделать ириску, как сделать картофельное тесто

морской фонарь как сделать, ебля интересная, как пишется сделать неаккуратно

Удачи!

профильная труба стальная proftruba-moscow.ru – идеальный материал для каркасов. в наличии квадратные и прямоугольные сечения с антикоррозийной обработкой.

мостбет скачать бесплатно [url=shorts.borda.ru/?1-18-0-00000397-000-0-0]shorts.borda.ru/?1-18-0-00000397-000-0-0[/url] .

Портал для любознательных https://lestomsk.ru/pochemu-angliyskiy-korol-nebes-kak-yazyk-shekspira-zavoeval-aviatsiyu/ Полезная информация, тренды, обзоры, советы и много вдохновляющего контента. Каждый день — повод зайти снова!

Здравствуйте!

Если вы хотите отслеживать показатели здоровья и улучшать физическую активность, информационные сайты помогут вам выбрать лучшие гаджеты для этого. В статьях рассматриваются устройства для контроля за состоянием организма, такие как фитнес-браслеты, спортивные часы и пульсометры. Сайты дают советы по выбору гаджетов для активных людей, которые следят за своим здоровьем. Эти ресурсы помогут вам улучшить физическую форму и следить за состоянием здоровья.

Как научиться быть более внимательным к деталям? Учитесь сосредотачиваться на процессе, а не только на конечном результате.

Больше информации по ссылке – https://onello.ru/

как сделать уголок, интересные факты про крым, интересные раст сервера

фильмы дисней интересные, как правильно сделать куни, вопросы интересные для детей

Удачи!

Добрый день!

Как улучшить качество жизни? Уделяйте внимание своему здоровью, окружайте себя позитивными людьми и старайтесь делать то, что приносит радость.

Как сохранить здоровые отношения с друзьями? Честность, открытость и уважение — это ключевые компоненты крепких дружеских отношений. Слушайте друг друга, поддерживайте в трудные моменты и старайтесь проводить время вместе, не забывая о том, что важно сохранять и свои личные границы.

Больше информации по ссылке – https://ptello.ru

медовый массаж лица чем полезен, статьи интересные обо всем, продукты богаты белками список какие

парашют как сделать, как сделать шоколадный мусс, города россии куда поехать

Удачи!

маркетплейс цифровых аккаунтов покупка аккаунтов соц сетей

продать аккаунт покупка продажа аккаунтов

Здравствуйте!

Как стать более инициативным? Проявляйте активность, предлагайте идеи и не ждите, что кто-то другой примет решение.

На информационных сайтах можно найти гаджеты для улучшения отношений и интимной жизни. В статьях рассматриваются устройства, которые помогают повысить сексуальную активность, улучшить эрекцию и гармонизировать отношения. Сайты предлагают рекомендации по использованию гаджетов для повышения либидо, улучшения сна и контроля гормонального фона. Эти ресурсы помогут вам улучшить качество интимной жизни и укрепить ваши отношения.

Больше информации по ссылке – https://asimuthaero.ru

вопросы для парня интересные, как сделать печку, интересные фильмы 2023

какие детективы стоит посмотреть сериалы, внутренний шов как сделать, как говядину сделать мягкой

Удачи!

Здравствуйте!

Как найти баланс между работой и личной жизнью? Устанавливайте четкие границы, выделяйте время для отдыха и поддерживайте здоровые отношения.

Как наладить отношения с коллегами? Будьте открытыми, уважительными и проявляйте эмпатию. Слушайте коллег, поддерживайте их идеи и всегда стремитесь к конструктивному взаимодействию.

Больше информации по ссылке – https://tyrtsia.ru/

как сделать управление жестами, кумыс как сделать, ролл как сделать

как сделать принт скрин, как сделать театр теней, турция интересные факты

Удачи!

mostbet kg скачать [url=https://tagilshops.forum24.ru/?1-4-0-00000205-000-0-0/]https://tagilshops.forum24.ru/?1-4-0-00000205-000-0-0/[/url] .

Доброго!

Как научиться видеть возможности вместо препятствий? Смените взгляд на проблемы, воспринимайте их как шанс для роста и развития.

Как научиться быть более организованным? Составляйте списки задач, придерживайтесь планов и создавайте порядок вокруг себя.

Больше информации по ссылке – https://azimuhtaero.ru/

факты про достоевского интересные, как сделать верхнюю запятую, как сделать девушке оргазм

инн как сделать новорожденному, как быстрее набрать мышечную массу, фильм мелодрама интересный

Удачи!

куплю продажа аккаунтов магазин продажи аккаунтов

Здравствуйте!

На информационном сайте можно найти ответы на самые разнообразные вопросы, включая темы о здоровье животных, уходе за питомцами, и воспитании домашних любимцев. Тут обсуждаются все аспекты от кормления до медицинских проблем, которые могут возникать у ваших питомцев. Темы о том, как приучить собаку к туалету или как выбрать лучшего врача для кошки, рассматриваются в подробных статьях. Такой сайт поможет вам сориентироваться в вопросах ухода за питомцем, предоставив множество полезных рекомендаций. Здесь также найдете информацию о том, как выбрать лучший корм для собак или как ухаживать за шерстью кошек.

Как справиться с неудачами? Не воспринимайте неудачи как конец, а как возможность для роста. Учитесь анализировать ошибки, извлекать уроки и двигаться дальше.

Больше информации по ссылке – https://asimutaero.ru/

самые полезные орехи рейтинг, жорж бизе интересные факты, как сделать дома мороженое

поделка интересная из бумаги, интересные факты о конфуции, интересные факты о плодах

Удачи!

Доброго!

На информационных сайтах также можно найти полезную информацию о гаджетах для путешественников. В статьях рассматриваются устройства, которые помогут вам в поездках, такие как портативные зарядные устройства, наушники с шумоподавлением и другие аксессуары. Сайты предлагают советы по выбору гаджетов, которые облегчат вашу жизнь в дороге. Также рассматриваются вопросы о том, как выбрать гаджеты для комфортного путешествия и работы в пути. Эти ресурсы помогут вам собрать идеальный набор гаджетов для путешествий.

Информационные сайты предлагают разнообразие гаджетов для контроля за состоянием здоровья. В статьях можно найти информацию о таких устройствах, как пульсометры, глюкометры, тонометры и умные весы. Сайты подробно рассказывают, как использовать эти гаджеты для самостоятельного мониторинга состояния здоровья и профилактики заболеваний. Также даются рекомендации по использованию гаджетов в сочетании с медицинскими процедурами. Эти ресурсы помогут вам заботиться о своем здоровье с помощью технологий.

Больше информации по ссылке – https://piano-quartet.ru

как сделать бесконечный шоколад, книги интересные для чтения, интересные факты о клеопатре

моря россии куда поехать, при отравлении озноб что делать, как сделать банкротство бесплатно

Удачи!

Ремонт помещений ремонт складов под ключ: офисы, отели, склады. Полный комплекс строительно-отделочных работ, от черновой отделки до финишного дизайна.

оценка стоимости квартиры сбербанк ocenka-zagorod

типография спб напечатать книгу типография спб

типография коробки на заказ https://mir-poligrafiya.ru

Привет всем!

Как развить устойчивость к стрессу? Начните с того, чтобы научиться осознавать свои эмоции и управлять ими. Практикуйте дыхательные упражнения и медитацию. Устойчивость к стрессу развивается с опытом и вниманием к своему состоянию.

Для улучшения интимных отношений и сексуальной жизни информационные сайты предлагают гаджеты для мониторинга здоровья и повышения либидо. В статьях рассматриваются устройства, которые помогают отслеживать гормональный фон, улучшать физическую активность и снижать уровень стресса. Сайты дают советы по выбору гаджетов, которые могут улучшить интимные отношения и обогатить сексуальную жизнь. Эти ресурсы помогут вам стать более уверенным в интимной сфере.

Больше информации по ссылке – https://nikita-bywalino.ru

интересные факты москва, интересно текст земфира, курорты зимой куда поехать россии

интересный рецепт, когда лучше есть протеиновый батончик, как сделать громче телефон

Удачи!

грузчики услуги заказать грузчиков недорого

дешево заказать грузчиков заказать грузчиков недорого

услуги грузчиков городу https://toguchin.standart-express.ru

1 вин вход в личный кабинет [url=http://yamama.forum24.ru/?1-11-0-00000459-000-0-0-1742818616]http://yamama.forum24.ru/?1-11-0-00000459-000-0-0-1742818616[/url] .

Привет всем!

Как развить чувство благодарности? Регулярно записывайте вещи, за которые вы благодарны, и замечайте хорошие моменты даже в повседневной жизни.

Как научиться видеть позитивные стороны в любой ситуации? Постарайтесь фокусироваться на том, что можно извлечь из любой ситуации, даже если она кажется негативной.

Больше информации по ссылке – https://psihfak.ru/

как сделать рулет бисквитный, при отравлении щелочью что делать, как сделать рыбный фарш

интересные мультики для детей, как сделать майнкрафт повторитель, интересные факты о медведе

Удачи!

Доброго!

Как поддерживать мотивацию? Найдите свою внутреннюю мотивацию, понимая, почему вы хотите достичь своих целей. Разделите большие цели на маленькие шаги и празднуйте маленькие победы. Помните, что мотивация укрепляется действием.

Как развить эмоциональный интеллект? Слушайте свои эмоции и учитесь их распознавать. Работайте над эмпатией и стараясь понять чувства других. Управляйте своими реакциями в различных ситуациях.

Больше информации по ссылке – https://alcogolizmstop.ru/

как сделать zip архив, подкасты самые интересные, как сделать попкорн сырный

факты о науке интересные, ттакджи как сделать, хороший детективный сериал зарубежный

Удачи!

Добрый день!

Как улучшить качество жизни? Уделяйте внимание своему здоровью, окружайте себя позитивными людьми и старайтесь делать то, что приносит радость.

На информационных сайтах можно найти информацию о гаджетах для контроля за состоянием здоровья. В статьях рассматриваются устройства, такие как фитнес-трекеры, пульсометры и умные часы, которые помогают отслеживать физическую активность, уровень стресса и качество сна. Сайты дают советы по выбору гаджетов для людей с разными целями: от похудения до контроля хронических заболеваний. Эти ресурсы помогут вам выбрать устройства, которые помогут вам оставаться здоровым и активным.

Больше информации по ссылке – https://relation1.ru

аниме интересные, жидкий азот как сделать, интересные факты про чайковского

продукты в пост богатые белком, куда поехать весной в россии, блинчик как сделать

Удачи!

Здравствуйте!

Как повысить свою продуктивность? Разбейте большие задачи на более мелкие и сосредоточьтесь на одном деле. Используйте методы, такие как техника помодоро, чтобы поддерживать высокий уровень энергии.

Как развивать чувство юмора? Отключите страх осуждения, позволяйте себе смеяться, даже над собой, и находите веселье в обычных вещах.

Больше информации по ссылке – https://ffactor.ru/

про японию интересные факты, шрифты скачать интересные, как сделать варенье густым

парадоксы интересные, как сделать красивый дом, искусственный камень как сделать

Удачи!

Продажа путёвок camp-centr.com. Спортивные, творческие и тематические смены. Весёлый и безопасный отдых под присмотром педагогов и аниматоров. Бронируйте онлайн!

печать визиток онлайн печать визиток

мотбет [url=www.maksipolinovtsu.forum24.ru/?1-1-0-00000194-000-0-0-1742815870]www.maksipolinovtsu.forum24.ru/?1-1-0-00000194-000-0-0-1742815870[/url] .

1вин вход с компьютера [url=www.mymoscow.forum24.ru/?1-6-0-00026928-000-0-0]www.mymoscow.forum24.ru/?1-6-0-00026928-000-0-0[/url] .

сервис магазина аккаунтов akkaunt-market.ru

Доброго!

Как научиться отпускать? Признайте, что не все в жизни поддается контролю. Отпускание — это акт доверия к жизни. Отпустите прошлое, не зацикливайтесь на сожалениях и позвольте себе двигаться вперед.

Как развить уверенность в себе? Работайте над своим внутренним состоянием, ставьте цели и активно двигайтесь к их достижению.

Больше информации по ссылке – https://lala-express.ru

как сделать кошелек электронный, как сделать интернет магазин, интересный фильм для детей

интересные факты о дирижерах, москва интересные экскурсии, фото интересные девушки

Удачи!

Здравствуйте!

На информационных сайтах можно найти обзоры лучших гаджетов для умного дома. В статьях подробно рассказывается о различных устройствах, таких как умные лампочки, термостаты, камеры безопасности и многое другое. Сайты дают рекомендации по выбору и настройке этих гаджетов для максимального комфорта и безопасности. Также рассматриваются вопросы интеграции гаджетов с другими устройствами в доме. Эти ресурсы помогут вам сделать ваш дом умным и удобным с помощью технологий.

Как избавиться от негативных мыслей? Начните с того, чтобы осознанно заменять негативные мысли на позитивные. Практикуйте благодарность и фокусируйтесь на том, что вам нравится в жизни. Эмоции поддаются изменению, если вы научитесь направлять внимание.

Больше информации по ссылке – https://kyocera-mds.ru/

интересные факты маяковского владимира, скан айфон как сделать, булгаков михаил интересные факты

как сделать iso образ, шкварки как сделать, смотреть новинки интересные фильмы

Удачи!

Здравствуйте!

Если вы хотите следить за своим здоровьем с помощью технологий, информационные сайты предложат массу полезных рекомендаций. В статьях рассматриваются гаджеты для измерения артериального давления, уровня сахара в крови и других показателей здоровья. Сайты помогают выбрать устройства для домашнего использования, которые помогут вам контролировать свое состояние. Также рассматриваются лучшие устройства для мониторинга физической активности и похудения. Эти ресурсы помогут вам выбрать гаджеты, которые заботятся о вашем здоровье.

Как научиться быть более гибким в жизни? Учитесь адаптироваться к изменениям, не сопротивляйтесь им, а ищите способы сделать их частью своей жизни.

Больше информации по ссылке – https://art-novosibirsk.ru

как сделать html ссылку, интересные сериалы исторические, скачать интересный фильм

сиреневый как сделать, куда поехать летом отдыхать россия, как сделать голос мягче

Удачи!

Выполняем качественное https://energopto.ru/raboty/montazh/mintazh-itp-ctp/ под ключ. Энергоэффективные решения для домов, офисов, промышленных объектов. Гарантия, соблюдение СНиП и точные сроки!

печать бланков спб https://pechat-blankov-spb.ru

печать фирменных папок печать папки а4

печать фото на холсте печать фото на холсте цена

dtf печать на заказ dtf печать оптом

широкоформатная печать стоимость shirokoformatnaya-pechat-spb.ru

что делать с бонусным балансом на 1win [url=https://www.dogzz.forum24.ru/?1-10-0-00000155-000-0-0-1742818537]что делать с бонусным балансом на 1win[/url] .

Привет всем!

Как эффективно решать проблемы? Разделите проблему на части, рассматривайте различные альтернативы решения и выберите оптимальный путь. Не бойтесь обратиться за помощью или советом.

Как избавиться от чувства вины? Примите свою ошибку и извлеките из нее уроки. Процесс прощения себя поможет вам освободиться от чувства вины и двигаться вперед с легкостью.

Больше информации по ссылке – https://drjahlov.ru

как сделать на, лучшие книги по корпоративным финансам, самая лучшая авиакомпания мира

как сделать мем, скачать кино интересное, интересно смайлик

Удачи!

мастбет [url=https://ashapiter0.forum24.ru/?1-19-0-00001444-000-0-0-1742819001]https://ashapiter0.forum24.ru/?1-19-0-00001444-000-0-0-1742819001[/url] .

1вин про [url=https://www.zdorovie.forum24.ru/?1-7-0-00000231-000-0-0-1742818050]https://www.zdorovie.forum24.ru/?1-7-0-00000231-000-0-0-1742818050[/url] .

Юридические услуги urwork в Санкт-Петербурге и Москве – от консультации до защиты интересов в суде. Оперативно, надежно и с гарантией конфиденциальности.

seo продвижение заказать поисковую оптимизацию

Выполняем проектирование https://energopto.ru и монтаж всех видов инженерных систем для жилых и коммерческих объектов. Профессиональный подход, сертифицированное оборудование, гарантия качества.

Планируете каникулы? купить https://camp-centr.com! Интересные программы, безопасность, забота и яркие эмоции. Бронируйте заранее — количество мест ограничено!

1 win вход [url=https://www.knowledge.forum24.ru/?1-0-0-00000101-000-0-0-1742817704]1 win вход[/url] .

MetaMask Chrome is excellent for crypto traders. The convenience of accessing dApps and swapping tokens directly is unmatched.

мосбет [url=https://www.girikms.forum24.ru/?1-1-0-00000361-000-0-0-1742819287]мосбет[/url] .

mostbet kg скачать [url=http://kharkovbynight.forum24.ru/?1-15-0-00003047-000-0-0/]http://kharkovbynight.forum24.ru/?1-15-0-00003047-000-0-0/[/url] .

Печать рекламных буклетов https://tipografiya-buklety.ru ярко, качественно, профессионально. Форматы A4, евро, индивидуальные размеры. Работаем с частными и корпоративными заказами.

buy anabolic steroids https://anabolshop.org

программа 1с бухгалтерия цена [url=https://moskovsky.borda.ru/?1-4-0-00000467-000-0-0-1742894547]программа 1с бухгалтерия цена[/url] .

масляные трансформаторы [url=www.masa.forum24.ru/?1-8-0-00000628-000-0-0]масляные трансформаторы[/url] .

результат анализа крови на вич купить результаты анализов вич купить

купить результаты анализов спб купить справку анализы

mostbet скачать [url=https://www.mostbet6005.ru]https://www.mostbet6005.ru[/url] .

купить кебаб купить кебаб

один вин [url=www.obmen.forum24.ru/?1-1-0-00004428-000-0-0-1742816292]www.obmen.forum24.ru/?1-1-0-00004428-000-0-0-1742816292[/url] .

Топ сайтов кейсов CS2 https://ggdrop.cs2-case.org проверенные сервисы с высоким шансом дропа, промокодами и моментальными выводами. Только актуальные и безопасные платформы!

служба поддержки мостбет номер телефона [url=www.alfatraders.borda.ru/?1-0-0-00004917-000-0-0-1743053068]служба поддержки мостбет номер телефона[/url] .

MetaMask Download is a smart move for investors. Keeping assets safe while accessing blockchain networks has never been easier.

мостбет казино [url=http://severussnape.borda.ru/?1-10-0-00000023-000-0-0-1743053372]http://severussnape.borda.ru/?1-10-0-00000023-000-0-0-1743053372[/url] .

скачать мостбет [url=assa0.myqip.ru/?1-23-0-00000149-000-0-0-1743053201]assa0.myqip.ru/?1-23-0-00000149-000-0-0-1743053201[/url] .

mostbet официальный сайт [url=https://cah.forum24.ru/?1-3-0-00000096-000-0-0-1743053764/]https://cah.forum24.ru/?1-3-0-00000096-000-0-0-1743053764/[/url] .

1 вин официальный сайт [url=fanfiction.borda.ru/?1-0-0-00029708-000-0-0-1743051664]fanfiction.borda.ru/?1-0-0-00029708-000-0-0-1743051664[/url] .

Доброго!

Вы слышали когда-нибудь о X GPT Writer, X Parser light или X Translator?

Я тоже нет, пока не посоветовали автоматизировать рутинные задачи этим софтом, хочу сказать одно! Я потом долго не мог поверить,

что можно так автоматизировать рутинные задачи и главное получить на выходе 100% свежий контент, что будут на ура индексировать

поисковые системы)

X-GPTWriter уникальный контент генератор

С X-GPTWriter у вас есть уникальный контент генератор, который создаёт оригинальные материалы на любую тему. Этот инструмент идеально подходит для блогеров, маркетологов и владельцев сайтов, желающих повысить качество своего контента. X-GPTWriter помогает генерировать интересные статьи и посты, которые будут выделяться среди конкурентов. Благодаря простому интерфейсу вы сможете легко адаптировать текст под свои нужды. Попробуйте X-GPTWriter и убедитесь, как легко создавать уникальный контент!

X-Translator уникальный генератор контента

X-Translator — это ваш уникальный генератор контента, который поможет создавать оригинальные тексты для различных проектов. С его помощью вы сможете генерировать идеи, статьи и посты, которые будут интересны вашей аудитории. Этот генератор контента идеально подходит для блогеров, предпринимателей и маркетологов. Используйте X-Translator для повышения качества вашего контента и привлечения новых читателей. Попробуйте X-Translator и откройте для себя новые возможности для творчества!

Кстати, друг дал купон на скидку 40%: 94EB516BCF484B27

подробности где его вводить указаны на сайте: http://xtranslator.ru/x-gpt-writer

Стоит попробовать Друзья, там есть демо, все бесплатно, не пожалеете)

Секреты создания контента с ChatGPT

X-GPTWriter: мощный инструмент для контент-креации

генератор контента для сайта

уникальный генератор контента

xml парсер контента

X-Parser Light универсальный парсер контента php

парсер контента на dle

уникализатор текста хороший X-Translator

X-Translator что такое контент генератор

X-Parser Light парсер контента магазинов

[url=https://www.xtranslator.ru]X-Translator генератор контента на русском языке[/url]

Удачи!

1win казино [url=realistzoosafety.forum24.ru/?1-11-0-00001540-000-0-0-1742816894]realistzoosafety.forum24.ru/?1-11-0-00001540-000-0-0-1742816894[/url] .

зайти в 1вин [url=http://balashiha.myqip.ru/?1-12-0-00000437-000-0-0-1743258848/]http://balashiha.myqip.ru/?1-12-0-00000437-000-0-0-1743258848/[/url] .

ремонт посудомоек hansa мастер по ремонту стиральных машин

дренаж дачного участка под ключ [url=https://drenazh-uchastka-krasnodar.ru]дренаж дачного участка под ключ[/url] .

смета на устройство дренажа [url=http://drenazh-uchastka-rostov.ru]http://drenazh-uchastka-rostov.ru[/url] .

Кладбище в Видном vidnovskoe актуальные данные о захоронениях, помощь в организации похорон, услуги по благоустройству могил. Схема проезда, часы работы и контактная информация.

система контроля движения транспорта [url=https://kontrol-avto.ru]система контроля движения транспорта[/url] .

1win вход [url=http://alfatraders.borda.ru/?1-0-0-00004932-000-0-0-1743258210/]http://alfatraders.borda.ru/?1-0-0-00004932-000-0-0-1743258210/[/url] .

Привет всем!

Купить двери в баню в Москве по низкой цене от производителя. Широкий выбор, современные дизайны. Быстрая доставка и установка. Изготовим любую дверь под заказ. В наличии более 4000 дверей с гарантией. Бесплатный замер. https://dverpodkluch.ru/catalog/v-banyu/

Купить двери в кладовую в Москве по низкой цене от производителя. Широкий выбор, современные дизайны. Быстрая доставка и установка. Изготовим любую дверь под заказ. В наличии более 4000 дверей с гарантией. Бесплатный замер.

Дверь на склад, Двери внутреннего открывания с зеркалом, Уличная дверь в дом

Двери венге, [url=https://dverpodkluch.ru/catalog/antivandalnaya-dver-v-kvartiru/] Антивандальная дверь в квартиру. Купить в Москве с установкой.[/url], Противопожарные двери со стеклом

Удачи!

Аккредитованное агентство pravo-migranta.ru по аутстаффингу мигрантов и миграционному аутсорсингу. Оформление иностранных сотрудников без рисков. Бесплатная консультация и подбор решений под ваш бизнес.

цены wb под контролем [url=www.reprajser-wildberries.ru]цены wb под контролем[/url] .

https://corfu-tours.ru/

mostbet kg [url=http://svstrazh.forum24.ru/?1-18-0-00000136-000-0-0-1743260517/]mostbet kg[/url] .

Куршская коса из светлогорска экскурсия kurshskaya-kosa-ekskursii.ru

Find the Perfect Clock https://clocks-top.com for Any Space! Looking for high-quality clocks? At Top Clocks, we offer a wide selection, from alarm clocks to wall clocks, mantel clocks, and more. Whether you prefer modern, vintage, or smart clocks, we have the best options to enhance your home. Explore our collection and find the perfect timepiece today!

Женские хитрости и секреты красоты и моды, психологии отношений и кулинарии. Также наши статьи направлены на родителей и педагогов, интересующихся вопросами воспитания и обучения детей https://mentalar.ru/

детская одежда с надписями [url=www.dbkids.ru/]www.dbkids.ru/[/url] .

augmented reality story [url=https://augmented-reality-platform.ru]augmented reality story[/url] .

Ежедневные актуальные новости уходящего дня. Мы говорим о медицине, автопроме, обществе, науке и многом ином https://sp-piter.ru/

Добрый день!

Клининг дома – это профессиональная уборка вашего частного жилья. Мы предлагаем услуги генеральной уборки, мытья окон и уборки после ремонта. Наши специалисты используют только безопасные и экологичные моющие средства. Клининг дома – это гарантированная чистота и порядок. Позаботьтесь о своем доме с нами.

Уборка после ремонта СПб цена – это доступные расценки на профессиональную уборку. Мы устраняем строительную пыль, мусор и загрязнения. Наши специалисты используют современное оборудование. Мы гарантируем чистоту после ремонта. Узнайте уборка после ремонта СПб цена и закажите услугу.

Вся информация на сайте – https://service-cleanspb.ru/

уборка после смерти цена, генеральная уборка квартиры после ремонта, заказать уборку после ремонта

клининговые услуги санкт петербург, клининговая компания спб уборка квартир после ремонта, компания по уборке квартиры спб

Удачи!

Добрый день!

Процедура банкротства физического лица начинается с подачи заявления в суд, если долг превышает 500 000 рублей. При банкротстве физического лица определяются условия для погашения долгов через продажу имущества или реструктуризацию долга. Процедура позволяет избавиться от задолженности и начать жизнь с чистого листа. Важно понимать, что банкротство физического лица имеет свои риски и ограничения, такие как возможное лишение имущества. Перед подачей заявления на банкротство лучше проконсультироваться с юристом, чтобы избежать ошибок.

Вся информация на сайте – https://svoijurist.ru

приватизировать собственность, купил квартиру когда можно получить налоговый вычет в 2020, можно ли при покупке квартиры у родственников получить налоговый вычет

сколько действует справка 2 ндфл для налоговой на вычет квартиру, взяли ипотеку когда можно получить налоговый вычет по процентам, как оформить договор купли продажи

Удачи!

Хотите увеличить площадь своего жилья и улучшить её функциональность? Застеклить балкон — это разумное решение для любого дома: застеклить

Moderni nabytek vitrina na modely do kazdeho interieru – od minimalismu po klasiku. Vice nez 1000 modelu skladem. Online objednavka, pohodlna platba, pomoc navrhare. Zaridte svuj domov pohodlim!

Добрый день!

Мойка окон стоимость – это доступные расценки на чистку окон. Мы используем только безопасные моющие средства и современное оборудование. Наши специалисты работают быстро и качественно. Мы гарантируем прозрачность и безупречный вид ваших окон. Узнайте мойка окон стоимость и закажите услугу.

Сколько стоит уборка после ремонта – это важный вопрос для каждого. Мы предлагаем доступные цены на профессиональный клининг. Наши специалисты удаляют строительную пыль и мусор. Мы гарантируем чистоту и порядок. Узнайте сколько стоит уборка после ремонта прямо сейчас.

Вся информация на сайте – https://service-cleanspb.ru/

генеральная уборка после ремонта, уборка квартир стоимость спб, уборка квартир санкт петербург

стоимость уборки квартиры после ремонта, уборка дома после ремонта, уборка загородного дома спб

Удачи!

Все про уход за лицом и телом. Массаж, полезные упражнения, косметология, очищение и многое другое на страницах нашего блога https://facesave.ru/