Vacuum Casting Materials: A Comprehensive Guide

Vacuum casting is a widely used manufacturing process in various industries. It is a cost-effective method of producing parts in small quantities with high accuracy and consistency. One of the crucial aspects of vacuum casting is selecting the right materials for the process. In this article, we will explore the most common vacuum casting materials, their properties, and their applications.

Table of Contents

- We are a renowned vacuum casting factory in China

- Importance of Material Selection in Vacuum Casting

- Common Vacuum Casting Materials

- Polyurethane (PU)

- Silicone Rubber (SR)

- Epoxy Resin (ER)

- Acrylic (PMMA)

- Nylon (PA)

- Polycarbonate (PC)

- Polypropylene (PP)

- ABS (Acrylonitrile Butadiene Styrene)

- POM (Polyoxymethylene)

- PET (Polyethylene Terephthalate)

- Factors to Consider When Selecting Vacuum Casting Materials

- Mechanical Properties

- Chemical Resistance

- Temperature Resistance

- Cost

- Applications of Vacuum Casting Materials

- Automotive Industry

- Medical Industry

- Consumer Products

- Aerospace Industry

- Best Practices for Vacuum Casting Material Selection

Introduction to Vacuum Casting Services from China Renowned Manufacturer

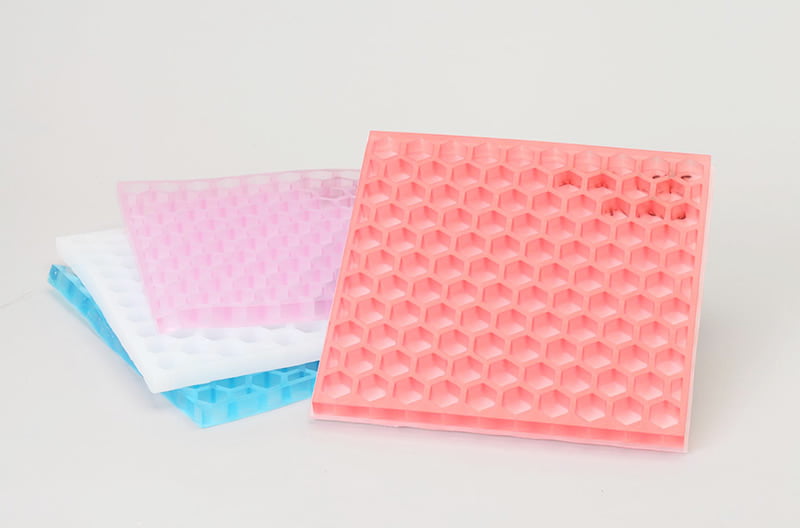

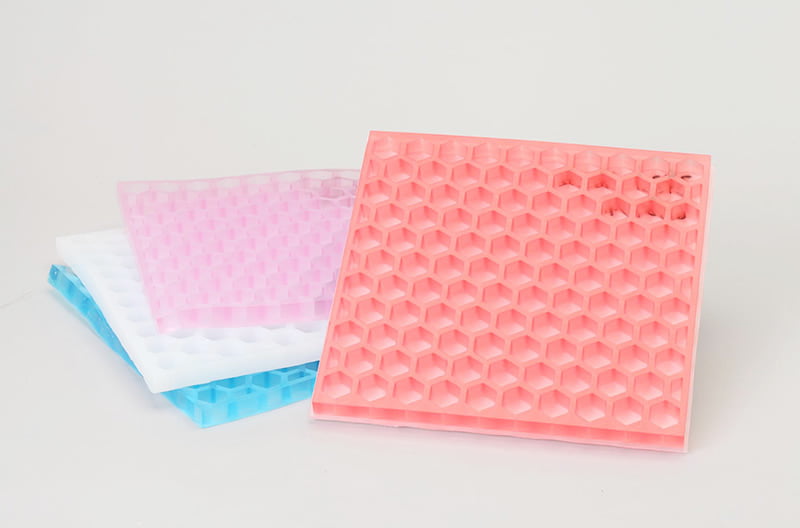

Tengrui is a renowned vacuum casting manufacturer in China, offering a completed solution to small series low volume manufacturing productions. Staring from the scratch of 3D model optimization, through 1st prototyping making, improve and finalize the 3D model drawing, low volume production and color customization, to the packaging & delivery. We have vacuum casted thousands of products across a wide range of products categories: medical devices, car parts, household appliances, cradles…etc., various of materials were adopted, hereby, we’d like to talk about something on the vacuum casting materials.

Importance of Material Selection in Vacuum Casting

Material selection is a crucial aspect of the vacuum casting process. The material used must have the appropriate mechanical and chemical properties for the intended application. The material must also be compatible with the silicone mold and the vacuum casting process.

Selecting the right material for vacuum casting can significantly affect the quality, durability, and performance of the final product. The material must also be cost-effective, as the production cost can increase significantly if expensive materials are used.

Common Vacuum Casting Materials

Several materials can be used for vacuum casting, depending on the specific application. The most common vacuum casting materials include:

Polyurethane (PU)

Polyurethane is a versatile material commonly used in vacuum casting. It is a synthetic polymer that can be tailored to have specific properties, including flexibility, rigidity, and hardness. Polyurethane can be pigmented to produce parts in various colors, making it suitable for a wide range of applications.

Silicone Rubber (SR)

Silicone rubber is a popular material for vacuum casting due to its excellent flexibility, durability, and chemical resistance. It is ideal for producing parts with intricate shapes and fine details.

Epoxy Resin (ER)

Epoxy resin is a high-strength material used in vacuum casting for producing parts that require high strength and durability. It can also be pigmented to produce parts in various colors.

Acrylic (PMMA)

Acrylic, also known as polymethyl methacrylate (PMMA), is a transparent material widely used in vacuum casting for producing parts with optical clarity. It is also lightweight, making it ideal for producing parts with low weight requirements.

Nylon (PA)

Nylon is a thermoplastic material commonly used in vacuum casting for producing parts that require high strength, toughness, and wear resistance. It can also withstand high temperatures and harsh chemicals.

Polycarbonate (PC)

Polycarbonate is a transparent thermoplastic material used in vacuum casting for producing parts with high impact resistance and optical clarity. It is also lightweight and has excellent heat resistance.

Polypropylene (PP)

Polypropylene is a thermoplastic material commonly used in vacuum casting for producing parts that require flexibility, chemical resistance, and low moisture absorption. It is also lightweight and has good fatigue resistance.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a thermoplastic material commonly used in vacuum casting for producing parts that require high impact resistance, toughness, and dimensional stability. It is also resistant to chemicals and heat.

POM (Polyoxymethylene)

POM is a thermoplastic material commonly used in vacuum casting for producing parts that require high strength, stiffness, and low friction. It is also resistant to chemicals and has good dimensional stability.

PET (Polyethylene Terephthalate)

PET is a thermoplastic material commonly used in vacuum casting for producing parts that require high strength, stiffness, and low moisture absorption. It is also lightweight and has good chemical resistance.

Factors to Consider When Selecting Vacuum Casting Materials

When selecting vacuum casting materials, several factors should be considered, including:

Mechanical Properties

The mechanical properties of the material, including tensile strength, compression strength, and impact resistance, should be considered based on the intended application.

Chemical Resistance

The material’s chemical resistance should be considered, as some materials may degrade or react with certain chemicals or environmental conditions.

Temperature Resistance

The material’s temperature resistance should be considered, as some materials may deform or lose their properties when exposed to high temperatures.

Cost

The cost of the material should be considered, as some materials may be more expensive than others, which can significantly affect the production cost.

Applications of Vacuum Casting Materials

Vacuum casting materials are widely used in various industries, including:

Automotive Industry

Vacuum casting is used in the automotive industry for producing small quantities of parts for prototypes, testing, and low-volume production.

Medical Industry

Vacuum casting is used in the medical industry for producing customized prosthetics, orthotics, and other medical devices.

Consumer Products

Vacuum casting is used in the consumer products industry for producing small quantities of parts for product design, testing, and low-volume production.

Aerospace Industry

Vacuum casting is used in the aerospace industry for producing parts for prototypes, testing, and low-volume production.

Best Practices for Vacuum Casting Material Selection

To ensure the best results when selecting vacuum casting materials, the following best practices should be followed:

- Consider the specific requirements of the application when selecting materials.

- Perform material testing to determine the suitability of the material for the intended application.

- Ensure that the material is compatible with the silicone mold and the vacuum casting process.

- Consider the production cost when selecting materials.

Looking for vacuum casting services from China? Either for low volume manufacturing of small quantity demanded products or pilot run prior to investing huge amount of cost in steel injection mold, we are offering a completed solution, visit us China Rapid Prototyping & Low Volume Manufacturing Factory! (vacuumcastingsz.com), as well as the specific vacuum casting page: Vacuum Casting Factory from China | Polyurethane Casting | Silicone Molding (vacuumcastingsz.com)

Mygreat learning I do not even understand how I ended up here, but I assumed this publish used to be great

Internet Chicks This was beautiful Admin. Thank you for your reflections.

Blue Techker Good post! We will be linking to this particularly great post on our site. Keep up the great writing

FinTech ZoomUs This was beautiful Admin. Thank you for your reflections.

Noodlemagazine This is quite fascinating, You’re a very talented blogger. I’ve subscribed to your feed and can’t wait for more of your magnificent posts. Additionally, I’ve shared your site on my social channels!

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

BusinessIraq.com stands as Iraq’s leading source for comprehensive business intelligence and economic updates, delivering real-time market insights to global investors and local entrepreneurs. Our platform provides extensive coverage of Iraq’s evolving business landscape, focusing on critical developments in oil and gas, infrastructure, and financial sectors. With expert analysis and breaking news, we ensure stakeholders remain informed about Iraq’s dynamic market opportunities.

BusinessIraq.com stands at the forefront of Iraqi business intelligence, delivering comprehensive coverage of the nation’s economic landscape. Our platform serves as the premier destination for breaking business news, market analysis, and industry insights across Iraq’s diverse commercial sectors. With real-time updates and expert commentary, we ensure stakeholders stay informed about the latest developments shaping Iraq’s business environment.

BusinessIraq.com excels in monitoring economic policy developments and their impact on business operations. From tax reforms to investment regulations, our platform keeps stakeholders informed about changes affecting business operations in Iraq. We provide regular updates on government economic initiatives, private sector responses, and international business community reactions, ensuring our readers stay ahead of market developments and opportunities.

Your article helped me a lot, is there any more related content? Thanks!

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://www.binance.com/si-LK/register?ref=V2H9AFPY

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your article helped me a lot, is there any more related content? Thanks!

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?