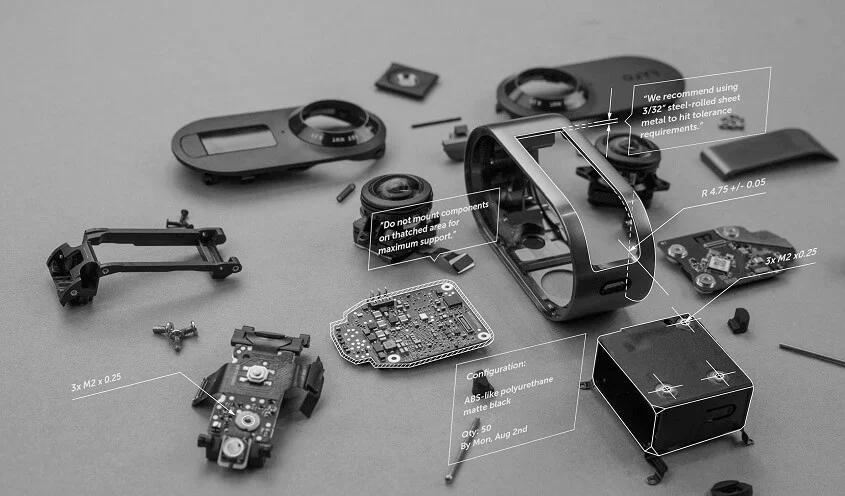

Making high quality prototypes is an important part of new product development, as it allows you to test and refine your design before investing in mass production with injection molding. Here are some tips on how to create high quality prototypes:

- Start with a clear design concept: Before creating a prototype, make sure you have a well-defined design concept that you want to bring to life. This will help you focus on the essential features and functions of your product.

- Choose the right materials: Selecting the appropriate materials for your prototype is crucial to ensure that it functions as intended. Consider the durability, strength, and other properties that are required for your product.

- Use CAD software: Computer-aided design (CAD) software can help you create accurate and precise 3D models of your product. This allows you to identify potential design issues before creating a physical prototype.

- Utilize rapid prototyping techniques: There are several rapid prototyping techniques available, including 3D printing, CNC machining, and injection molding. These methods can help you create prototypes quickly and cost-effectively.

- Test and refine your prototype: Once you have created a physical prototype, test it thoroughly to identify any design flaws or issues. Make adjustments as necessary and continue refining your prototype until it meets your desired specifications.

- Consider user feedback: Gather feedback from potential users or customers to further refine your prototype. This will help you identify any usability issues and make improvements to enhance the user experience.

Based on above fundamental rules, you can create high quality prototypes that will help you refine and perfect your new product design. However, you need also pay attention & think further to make high quality prototypes,

- Consider the manufacturing process: When creating a prototype, it’s important to keep in mind the eventual manufacturing process. This can help you identify any issues that may arise during production and make necessary adjustments to the design.

- Test different materials: Don’t be afraid to experiment with different materials when creating your prototype. Testing various materials can help you identify which ones work best for your product.

- Pay attention to details: Make sure your prototype is as accurate and detailed as possible. This can help you identify potential issues with the design and ensure that your product works as intended.

- Be flexible: Don’t be afraid to make changes to your prototype as you go along. Being flexible and open to new ideas can help you create a better final product.

- Seek feedback from experts: Consider getting feedback from experts in your industry, such as engineers or designers. This can provide valuable insights into the design and help you identify areas for improvement.

- Consider using simulation software: Simulation software can help you test your design in a virtual environment before creating a physical prototype. This can save time and money, as well as help you identify potential issues early on.

By incorporating these additional tips, you can create high-quality prototypes and make it is helpful to NPD projects.

If you are looking for prototype supplier from China, or even just at the beginning of a new project, please feel free to reach us for assistance: Rapid Prototyping and Low Volume Manufacturing Service in China! (vacuumcastingsz.com)

Tech to Force I truly appreciate your technique of writing a blog. I added it to my bookmark site list and will

Fantastic site. Lots of helpful information here. I am sending it to some friends ans additionally sharing in delicious. And of course, thanks for your effort!

Pink Withney For the reason that the admin of this site is working, no uncertainty very quickly it will be renowned, due to its quality contents.

Sky Scarlet I like the efforts you have put in this, regards for all the great content.

Technoob This is really interesting, You’re a very skilled blogger. I’ve joined your feed and look forward to seeking more of your magnificent post. Also, I’ve shared your site in my social networks!

Insanont I am truly thankful to the owner of this web site who has shared this fantastic piece of writing at at this place.

Tech Learner Very well presented. Every quote was awesome and thanks for sharing the content. Keep sharing and keep motivating others.

Hi! I noticed you visited my site, so I’m returning the favor. I’m looking for ideas to improve my own site, and I appreciate the inspiration. Hope it’s okay if I take some cues from here.

Your article helped me a lot, is there any more related content? Thanks!

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your article helped me a lot, is there any more related content? Thanks! https://www.binance.com/ka-GE/join?ref=RQUR4BEO

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://www.binance.com/join?ref=P9L9FQKY

Your article helped me a lot, is there any more related content? Thanks! https://www.binance.com/fr-AF/register?ref=JHQQKNKN

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your posts are always so well-written and thought out It’s evident that you put a lot of effort into each and every one

I am extremely impressed along with your writing skills as well as with the format on your blog. Is that this a paid subject matter or did you modify it yourself? Anyway keep up the nice high quality writing, it’s uncommon to peer a great weblog like this one these days!

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your article helped me a lot, is there any more related content? Thanks!

Your article helped me a lot, is there any more related content? Thanks! https://www.binance.com/join?ref=P9L9FQKY

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your article helped me a lot, is there any more related content? Thanks!

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

buy amoxil online – order amoxil without prescription cheap generic amoxil

Thank you, your article surprised me, there is such an excellent point of view. Thank you for sharing, I learned a lot.

Thank you, your article surprised me, there is such an excellent point of view. Thank you for sharing, I learned a lot.

cialis free trial 2018 – buy cialis shipment to russia tadalafil generic reviews